Coil Manufacturing

Ridgway Machines manufactures a full range of Coil Manufacturing Equipment, including Rotor Winders, Loop Winders and ancillary equipment such as Capstan Tension Units, Winding Beams and Drum Stands.

Manufactured to high specifications and incorporate the latest safety features and fully programmable operator control.

Ridgway Machines also manufactures a range of Coil Pull-Out Machines.

Ridgway W-LAP Loop Winding Machine

with automatic pin positioning and active drum tensioning

Designed for the precision winding of looped coil

Technical Specification

Loop Winder

Maximum torque

Up to 8500 Nm

Speed range

0 to 25 rpm

Fully programmable operator HMI

Winding Beam

Maximum loop length

Up to 4.5 metres

Servo controlled winding pin positioning

Quick Release Tooling

‘D’ Tooling for Trapezoidal shaped coils

Pay Off Drum Stand

Drum shaft diameter

Ø 32mm

Maximum number of drums

Up to 26

Maximum drum diameter

Ø 800mm

Maximum drum width

300mm

Maximum drum weight

150kg

![]() Improved Quality

Improved Quality

![]() Programmable winding pin positioning

Programmable winding pin positioning

![]() Servo motor drives

Servo motor drives

![]() Anti runback

Anti runback

![]() Quick release tooling

Quick release tooling

![]() Conductor active tensioning

Conductor active tensioning

![]() Operator HMI Control

Operator HMI Control

Other functions include the ability to set and count the number of turns per coil and the quantity of coils per set.

Coil winding details can also be stored within the control system for future use.

![]() Cost effective solution

Cost effective solution

Technical Specification

Heavy Duty Loop Winder

Maximum torque

Up to 8500 Nm

Speed range

0 to 20 rpm

Fully Programmable and full auto control or manual mode available

Heavy Duty Winding Beam

Maximum & Minimum loop length

500 – 4,500mm

Servo controlled pin positioning

Auto Quick Release at end of winding

‘Squirrel’ Tape Turner & Support Gantry

STT Rotation Taping Speed

up to 200rpm

STT Linear Speed

6m per minute maximum

Number of Tape Pads

1 to 3

Maximum Tape Pad Diameter

180mm

Maximum Conductor Stack

30 x 30 mm

Ridgway W-LAP Heavy Duty – Loop Line

with in-line turn taper

Designed for the precision winding of large looped coils

Programmable Operator Interface and Control System for:

![]() Loop Recipe and Selection

Loop Recipe and Selection

- Required number of turns

- Winder maximum rotational speed

- Conductor clamping

- Pin position setting

- Mode: Manual Loop, Auto Loop, Auto with Tape

![]() Taping Parameters Recipe

Taping Parameters Recipe

- Auto calculation & display of amount of tape required per coil loop

- Scaling of Turn Taper linear and rotation maximum speeds

- Amount of conductor used per coil loop

- Tape break detection

- Tape remaining calculation

- Calculation of pitch setting and tape pad angles

- Auto lead tape length at end of process

![]() Servo drive and position control of Turn Taper Gantry

Servo drive and position control of Turn Taper Gantry

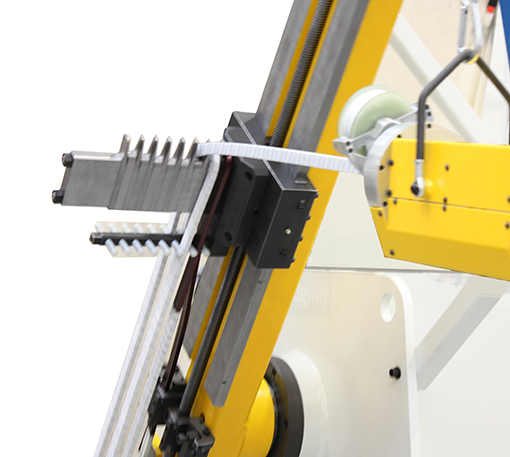

Ridgway Squirrel Turn Taping Machine

Designed for the efficient taping together of multiple conductors as they pass

between the gathering box and loop winding beam during the loop winding process.

For a versatile and cost effective solution, the STT Squirrel turn taping machine offers a simple solution to dramatically reduce the overall coil manufacturing time.

By introducing the STT between the gathering box and loop winding machine, groups of conductors can be quickly and accurately taped together with minimal disruption to the winding process.

![]() Freely suspended

Freely suspended

![]() Variable lap

Variable lap

![]() Servo drives

Servo drives

![]() Gantry sizes

Gantry sizes

![]() Traction control

Traction control

![]() Twin tape applicators

Twin tape applicators

![]() Tape tension

Tape tension

![]() Operator control pedestal

Operator control pedestal

Technical Specification

Rotational speed

200rpm

Linear speed

Max: 6m/min

Tape pad diameter

Max: Ø100mm (24”)

Tape width

20mm and 25mm

Tape spool core

Ø10mm bore

Ø25mm bore

Tape tension

Max: 1kg (2.2lbs) for glass taping

Max: 5Kg (11lbs) for mica taping

Conductor stack size

Max: 25mm wide x 25mm high

More machines in our coil manufacturing and winding range

Ridgway W-LMP Loop Winding Machine

Designed to offer a comprehensive range of modern, easy to use, accurate loop winding machines

For a versatile and cost effective solution to suit your loop winding requirements.

Sturdy construction, free standing control panel and digital turns counter are key features of our loop winding solutions.

The loop winding machine offers quick and accurate set up, vector motor drive, anti runback and easy to operate control panel.

Technical Specification

Up to 8500 Nm

Speed range

0 to 25 rpm

Bi-directional

Maximum loop length

Up to 4.5 metres

Pin diameter

Min. Ø 15mm – Max. Ø 80mm

Quick Release Tooling

‘D’ Tooling for Trapezoidal shaped coils

Quick release winding pins

Drum shaft diameter

Ø 32mm

Maximum number of drums

Up to 26

Maximum drum diameter

Ø 800mm

Maximum drum width

300mm

Maximum drum weight

150kg

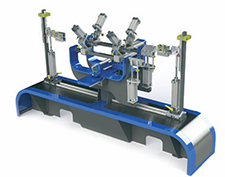

Ridgway W-MAW Loop Winding Machine

Designed for the automated production of complex coils, from on edge field coils to wind turbine stator coils.

Improve production effectiveness by utilizing the Ridgway W-MAW.

Incorporating a programmable multi-axis winding machine with active drum tensioning and conductor guidance systems, the equipment ensures fast, consistent and high quality production of complex shaped stator coils.

Automatic winding without the need for operator intervention.

Technical Specification

Loop Winder

Maximum torque

Up to 9000 Nm

Speed range

0 to 10 rpm

Fully programmable

Winding Beam

Maximum length

Up to 2.5 metres

Servo controlled beam positioning

Servo controlled tool rotation

Ridgway W-RHD Rotor Winding Machine

Designed for bi-directional, indexed winding of rotor pole coils

Technical Specification

Up to 10000 Nm

Speed range

0 to 10 rpm

Maximum rotor weight

W-RHD5000 – up to 5000kg

W-RHD10000 – up to 10000kg

Faceplate centre height

1300mm (other heights available)

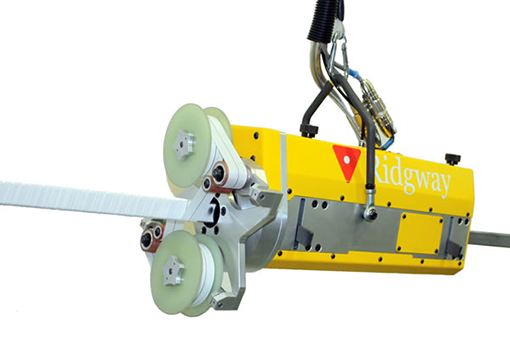

Ridgway Capstan Tension Unit

Variable tension control

Adjustable guide rollers

Pneumatic brake override

![]() Geared servo drive system

Geared servo drive system

![]() Pneumatic holding brake

Pneumatic holding brake

![]() Operator controls

Operator controls

![]() Drum stands

Drum stands

![]() Indexing

Indexing

![]() Tooling and fixtures

Tooling and fixtures

Coil Pull-Out Machines

Ridgway Machines manufactures a range of Coil Pull-Out and Coil Forming Machines.

Manufactured to high specifications and incorporate the latest safety features and fully programmable operator control.

POM-STD Coil Pull-Out Machine

POM5000 Coil Pull-Out Machine

POM-WPB Wind & Pull-Out Beam

POM-CC Continuous Coil Forming Machine

Technical Specification

Coil stack height

Dependent on tooling

Coil stack width

Dependent on tooling

Slot length

Max: 4064mm

Min: 115mm

Overall loop length (eye to eye)

Max: 5300mm

Min: 875mm

Angle between coil sides

Max: 120° (included)

Min: 0°

Offering a cost effective and versatile solution, the machines are fully adjustable and simple to operate.

Technical Specification

Coil stack height

Max: 85mm

Min: 12mm

Coil stack width

Max: 40mm

Min: 6mm

Length of cell (coil straight)

Max: 4128mm

Min: 440mm

Overall loop length (eye to eye)

Max: 5000mm

Min: 950mm – using extensions

Nose bend radii

25mm, 35mm, 50mm, 75mm

Core bend radii

25mm, 35mm, 50mm, 75mm

Coil nose pin diameter

Max: 63mm

Min: 20mm

Angle between coil sides

Max: 130°

Min: 20°

Coil spread

Max: 1200mm

Min: 400mm

Nose twist angle

Max: ± 30°

Min: 0°

The machine has the power to shape coils of the largest cross section and the flexibility to be adapted for different bend radius at the nose and in the core bend region.

Technical Specification

Coil stack height

Max: 50mm

Min: 10mm

Coil stack width

Max: 17mm

Min: 5mm

Length of cell (coil straight)

Max: 1520mm

Min: 440mm

Overall loop length (eye to eye)

Max: 2300mm

Min: 756mm

Winder

Maximum torque

Up to 5000 Nm

Speed range

0 to 20 rpm

Bi-directional

The POM-WPB enables phase groups of single and multi-turn coils to be loop wound and pulled-out in one operation.

Technical Specification

Coil stack height

Dependent on tooling

Coil stack width

Dependent on tooling

Length of cell (coil straight)

Max: 1000mm

Min: 380mm

Overall loop length (eye to eye)

Max: 2000mm

Min: 875mm

Angle between coil sides

Max: 120° (included)

Min: 0°

Coil spread

Max: 900mm

Min: 150mm

Enabling the fast and effective winding of stators, this turn-key production solution dramatically reduces the number of winding connections required. Simple to operate, production efficiencies of 50% can easily be achieved.

Technical Specification

Heating Temperature

Typically 165 degC

Compaction Force

10 Tonnes max from each pair of 15 hydraulic rams as standard

Coil Size Capacity

Width 360mm max/50mm min

Height 250mm max

Length 3810mm max

Hydraulic System

Powered by an air multiplier system

Preset to pneumatic pressure x 100

Heating Circuit

Up to 30 internal heater platens using Electrical elements and thermocouples

Cooling Circuit

2 bar initial air blast to heater bars

Chilled water sent to heater bars

Final air blast to remove all water

Operator Controls

Separate cabinet with touch screen

HMI display for full process control

Air Supply

5.5 bar maximum, clean dry air

Power Supply

440 volts 3 phase 50 hertz typical

Noise Exposure

Less than 75 Db(A)

CE Compliant

The HCP Hot Coil Compaction Press is designed to heat and consolidate straight loop stator coils, each machine tailored to the customer’s specific needs.

The HCP incorporates a set of hydraulic rams built into hinged arm assemblies across the top length and rear face of the working envelope, with independent hydraulic circuits. Each ram can deliver 10 tonnes of force and the number of rams can be selected to suit specific coil lengths.

Coil heating is achieved using a set of electrically heated platens (heater bars) at the front and rear sides of the machine. Each platen is independently operated/controlled from a freestanding HMI cabinet.

After pressure is applied, the platen temperature is raised to a set point and held for a period of time (soak time). The platens are then cooled with an air blast followed by recyclable cooling water prior to hydraulic ram release and unloading of the coils.

![]() Precision Coil Forming

Precision Coil Forming

The HCP Hot Coil Compaction Press is designed and assembled by experienced Ridgway engineers using high quality, robust components. This ensures that a uniform and precision compaction process is reliably achieved for a wide range of coil consolidation requirements and long term operational life.

![]() Full HMI Process Control

Full HMI Process Control

Full HMI operator control is provided from a freestanding cabinet. This covers the entire compaction process from hydraulic, air and temperature control to cooling and power consumption for each of the control zones within the machine, including fault diagnosis.

Hot Coil Compaction Press

Designed to heat and consolidate straight loop stator coils