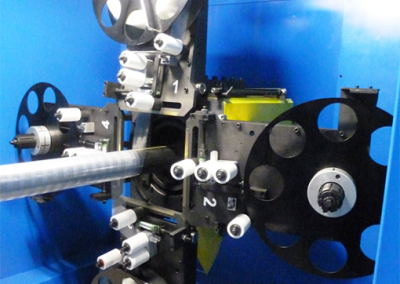

Umbilical cable taping machine

World leading taping machinery to manufacture subsea umbilical cables for the toughest conditions.

Overview

The Umbilical Taping Machine is designed to apply a variety of tapes to an umbilical as it passes through the machine. The tape head rotates to produce a spiral wrap of tapes on to the umbilical to a pre-programmed configuration. Tape tensions are accurately controlled and maintained as the tape pads are used.

![]() To manufacture a variety of umbilicals

To manufacture a variety of umbilicals

![]() Consistent and repeatable taping performance with active tension control

Consistent and repeatable taping performance with active tension control

![]() Tape package change without having to stop the line

Tape package change without having to stop the line

![]() Tape package change without hazard to the operator

Tape package change without hazard to the operator

![]() Improved quality and production

Improved quality and production

Technical Specification

Main machine: 7000kgs

Umbilical support unit: 2300kgs

Side beams (each): 650kgs

End iris guide support: 800kgs

Tape pad diameter: Up to 600mm

Tape pad width: 50mm to 80mm

Tape pad maximum weight: 35kg

Tape pad bore: 76 or 152mm cardboard

Number of tape pads: 1, 2, 3 or 4

Rotating speed: 0 to 50rpm maximum (use a half weight pad when using odd numbered tape pads)

Direction of Rotation: Clockwise and anti-clockwise

Time to accelerate to full speed: 10 seconds

Time to decelerate from full speed: 4 seconds

Taping angles: 50 to 88 degrees from pipe axis

Tape tension range: 10 – 40 kg ±15% (from full to empty tape pad)

Umbilical outside diameter range: 40 to 310mm

Bore of machine: 350mm

Centre line height: 1.175m

Machine dimensions: 10.83m long x 5.50m wide x 2.45m high

Power supply – electrical: 415 volts / 3 phase / 50 hertz

Environment: 0 to 28 degrees C with maximum 85% humidity