Other Cable and Conductor Equipment

Ridgway provide equipment for a range of wires, cables and conductors.

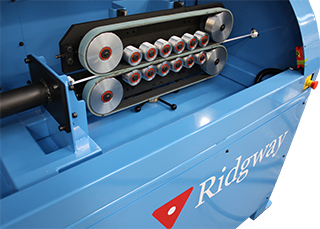

CATERPILLARS

for traction speed control

Designed to pull cables or conductors at a controlled speed without damaging the product covering.

Polyurethane laminated belts run on rollers. Grip is provided by the upper belt track closing down onto the lower track with the cable or conductor between the two tracks.

The single drive is through a gearbox arrangement to drive both belts at the same speed, with the overall control through a servo drive.

Caterpillars are designed in a variety of sizes with various line speeds, pulling forces and contact lengths to suit customer

requirements.

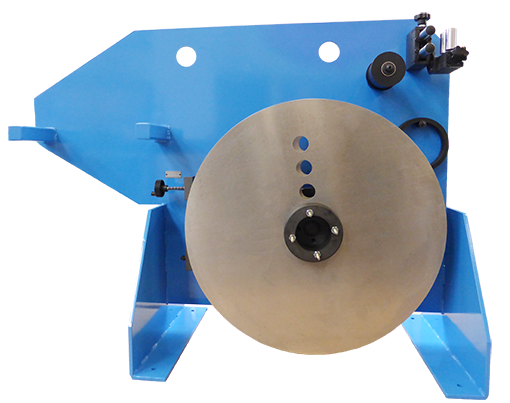

WIRE & CABLE ENCAPSULATION UNIT

The Wire and Cable Encapsulation Pay-Off Unit is designed to pay-off material for the encapsulation of electrical cables and wires.

A cable or wire is passed through the unit to encapsulate it within the specified covering. The encapsulation material is wound in a flat pad format and mounted onto the machines spindle. The encapsulation is produced by paying-off the encapsulation material, passing it over a guide roller, through a forming cone and then through a heated die.

The centre line of the machine is nominally 1000mm although this can be configured to suit the customers exact requirements.

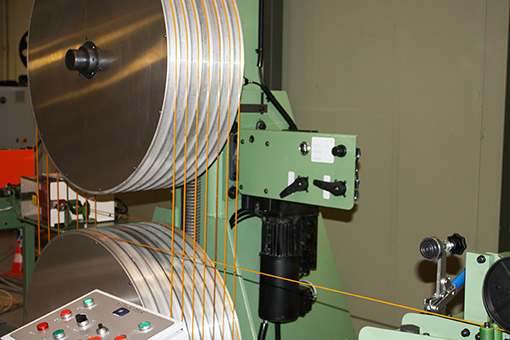

ACCUMULATORS

Vertical accumulators designed in a variety of sizes for different lengths and tensions.

The accumulator will also act as a dancer when small conductors are being used in conjunction with take-up drum stands.

In normal production, the accumulator top pulleys will be positioned close to the bottom pulleys. When the accumulation system is to be used, the top pulleys will move upwards enabling more conductor to be stored.

A geared motor unit complete with timing pulley provides the drive system. The top pulleys are also counter balanced to assist the drive system.

Accumulator installed on Kapton Cable and Conductor Taping Line.