Special Purpose Superconductor Taping Machines

Designed for quality insulation in world leading projects specializing in taping machinery for Superconductors and Superconducting Coil Manufacturing.

Wrapping systems for superconducting magnet coils

The machines are specifically designed to tape wrap Toroidal Field (TF) coils, Central Solenoid (CS) coils and Poloidal Field (PF) Coils.

Ridgway worked closely with world leading organisations General Atomics, Elytt Energy and SEA ALP Engineering Consortium to provide high technology critical components for the ITER project. The bespoke machine designs accommodated specific insulation taping system requirements whilst integrating into complex production machines while maintaining ease of operation

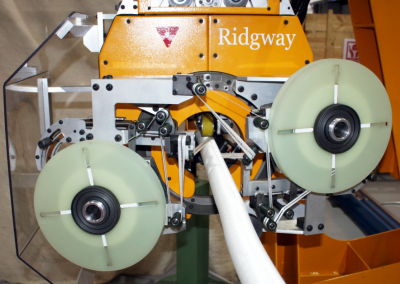

Wrapping Head

Conductor range: Ø43.7mm ±0.2mm

Rotational speed: 0 to 66rpm variable

Line speed: 0 to 1.0m/min variable

Acceleration time 5 seconds to full speed

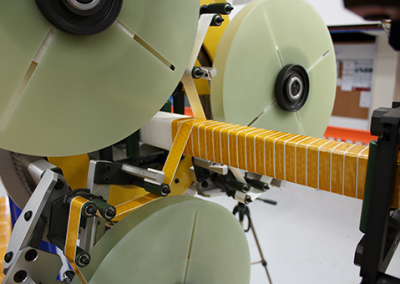

Wrapping Station

Conductor size: 52mm square with rounded corners

Rotational speed: 0 to 60rpm variable

Line speed: 0 to 1m/min variable

Acceleration time: 5 seconds to full speed

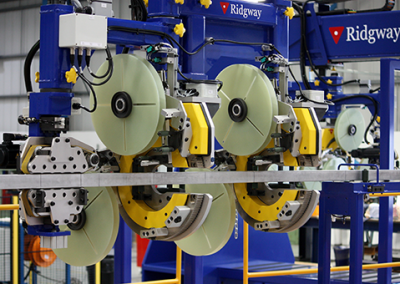

Taping machine for superconducting bus bars

Ridgway worked in close collaboration with the Engineering Team at CERN to ensure the bespoke machine design accommodated the special taping requirements and product handling needs of large superconducting bus bars for magnet connections for the Large Hadron Collider.

The machine design had to accommodate the application of special insulation materials capable of withstanding high electrical voltages and extreme operating temperatures, extremes of pressure and different operating media.

In addition, the machine provides flexible yet simple operator set up and ease of handling of the large superconducting bus bars to ensure efficient, trouble free production operation.

The BCT 75/135VL machine is intended for use with low resin or encapsulated resin tapes of 20mm (¾”) and 25mm (1”) width, which are applied at a variable overlap (typically ½ & 2/3) over the “in-slot” area and end legs of the coil or bar

BCT 75/135VL

| Capacity : | Max : 75mm wide x 155mm high |

| Tape Width : | 20mm (¾”) and 25mm (1”) |

| Tape Tension : | Adjustable 1.0kg to 14.0kg |

| Tape Spool : | 25mm Æ core; 170mm Æ outside. |

| Compressed Air Supply : | 5,5 Bar pressure. Use of airline with a minimum bore of 12mm is recommended.

The machine will use approximately 18 litres/sec of free air at full speed.

|

| Machine Taping Speed : | 150 rpm max. Top speed settable and acceleration controlled from the trigger. |

| Traverse Rate/Nominal Pitch : | Variable including 20mm tape 1/2, 2/3 and butt lap.

25mm tape and 1/2, and 2/3 lap. |

| Distance between coil legs for machine access : | 300mm Min. |

| Weight of Taping Unit : | 46kg |