OTHER TAPING EQUIPMENT

A range of taping machinery for the coil, cable and conductor manufacturing industries.

Narrow Coil Taping Machine

Designed for the efficient taping of narrow wind turbine generator stator coils.

Technical Specification

60rpm

Linear speed

1.0m/min

Tape width

20mm / 25mm

Pitch capability

5mm to 28mm

Tape tension

20N to 50N

Taping angle

+/- 20°

Coil length

Minimum: 700mm

Maximum: 3000mm

Min Distance between coil sides

Minimum: 65mm

Max Distance between coil sides

Maximum: 500mm

Coil cross section height

Minimum: 25mm

Maximum: 160mm

Coil cross section width

Minimum: 10mm

Maximum: 25mm

Maximum coil weight

200kg

Noise

Less than 80dB(A)

CE Compliant

The NCT features a unique multi-axis motion control system with a freestanding programmable HMI, making it a truly versatile machine that simplifies the precision taping of all narrow coil configurations, straight or diamond shaped.

The innovative design solves a common problem where traditional taping machines have limited access to both sides of the coil.

The coil support system features automatic coil turn-over and height adjustment. This simplifies set-up and eliminates the need to remove or reposition a coil to tape both sides, improving productivity.

Ridgway’s skilled and experienced engineers are also available for fast, professional support using remote machine diagnostics as necessary to assist the end user with specific operating conditions.

![]() Unique Taping Motion

Unique Taping Motion

![]() Constant Tension Control

Constant Tension Control

![]() Fully Programmable

Fully Programmable

![]() User Friendly HMI Control

User Friendly HMI Control

Technical Specification

Rotational speed

250rpm maximum

Tape width

25mm / 30mm

Tape head centre height

1040mm from floor level

Tape Spools

Two Spools ID 55mm/OD 200mm

Tape tension

0.5kg to 7.0kg direct pull

Tape feeding angle

Automatic. Correct angle always found either side of centre line

Straight Bar Length

(Slot Length)

Typically 4000mm maximum

Coil Cross Section

Maximum size 125mm x 60mm

Minimum size 50mm x 10mm

Coil Support System

Retractable pneumatic coil supports to suit maximum coil / bar length

Optional fully adjustable rear clamp stands

2 coil eye support clamping assemblies

Operator Controls

Carriage mounted for guard reset, bump strip reset, carriage/head drive

Air Supply

6 bar maximum, clean dry air

Power Supply

415 volts 3 phase 50 hz (other voltages available)

Noise

Less than 80dB(A)

CE Compliant

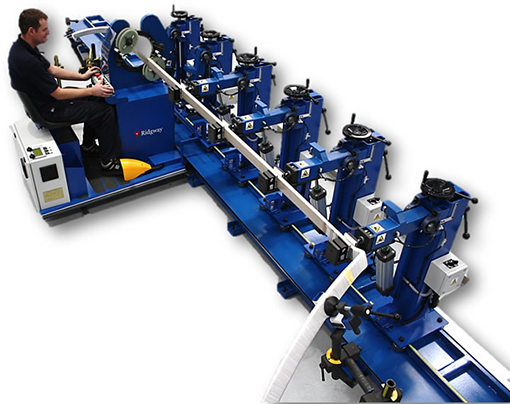

The MTM Mobile/Travelling Head Coil Taping Machine provides a unique solution to maximise the productivity of applying insulation tapes to larger size electrical coils or bars, with a typical slot length capacity of up to 4000mm.

Ridgway’s MTM is specifically designed for handling these larger size coils/bars using a combination of retractable pneumatic coil supports, adjustable rear clamp stands and coil eye supports.

The taping head is mounted on a mobile carriage which seats the operator and travels along the straight bar or straight leg of coil to be taped, in both directions.

As the carriage approaches the pneumatic coil supports, the clamps open automatically and the support arm moves away to the rear of the machine.

The MTM machine can be operated continuously in both directions, travel is simply reversed by the operator moving a joystick.

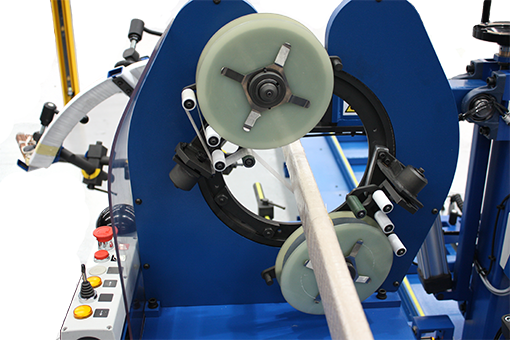

![]() Taping Head

Taping Head

The taping head rotates around the coil applying a pair of tapes simultaneously with the tension being settable between 0.5 and 7.0 kg. Tape reel carriers automatically follow the natural angle of the tape being applied to the coil in relation to the coil axis. The MTM head can apply tapes at a rotational speed of up to 250 rpm to maximise productivity.

![]() Drive System

Drive System

The MTM uses twin variable speed motors to provide and synchronise the taping head drive and carriage traverse functions. These are controlled by a foot pedal mounted on the taping head carriage, with reversing selection by joystick control.

![]() Coil Support

Coil Support

Pneumatically assisted coil support and clamping system with 3 retractable arms, fully adjustable rear clamp stands and coil eye clamps/supports.

![]() Operator Controls

Operator Controls

The operator controls for guard reset, bump strip reset, carriage direction selection and taping head drive controls are all mounted on the mobile carriage for ease of use. Factory pre-set acceleration and deceleration ramps ensure gentle start and stop operations.

![]() Safe Guarding

Safe Guarding

The MTM is equipped with fixed mesh screen guards on 3 sides for operator safety. On the open side of the machine enclosure an electronic light sensor guard automatically detects any intrusion and activates the safety circuit, cutting power to stop the machine.

Mobile/Travelling Head Coil Taping Machine

Designed for the efficient taping of large stator coils and bars