Coil Taping Machines

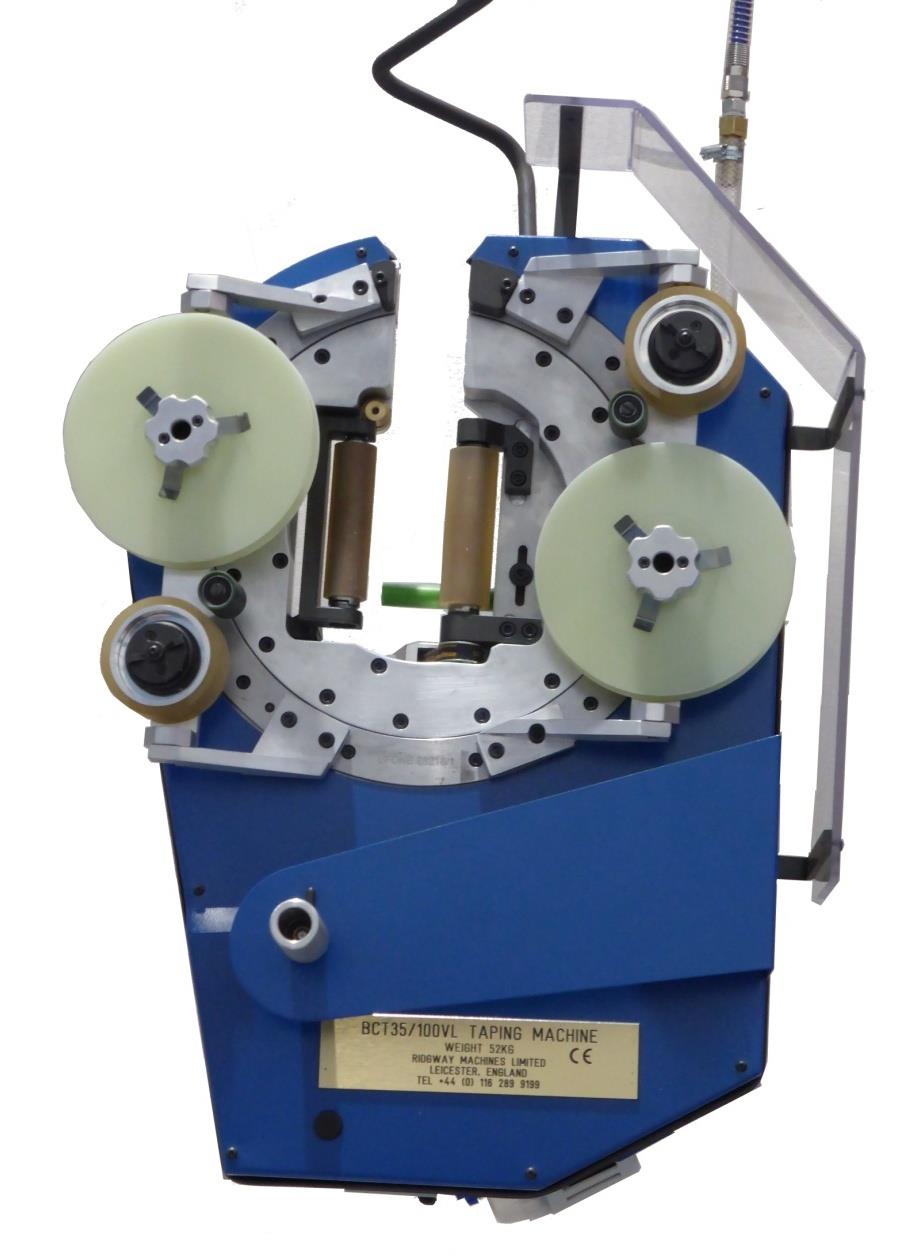

Designed for the fast, precision application of tape insulation systems to a wide variety of components – including motor and generator stator coils and bars. BCT Suspended Coil Taping Machines provide the ultimate solution to dramatically improve your production capabilities.

BCT Taping Machines

|

CAPACITY Cross Section of min Conductor being taped max |

| Tape Width |

| Lap |

|

Tape Spool Core Out Side Diameter |

| Tape Tension |

| Taping Speed |

| Air Supply |

| Recommended Min Bore |

| Free Air Use @ full speed |

| Bench – Mounted |

BCT16/30VL

5mm X 10mm

16mm X 30mm

15mm or 20mm

Variable

Ø25mm

Ø 80mm or 90mm

0.5kg – 6.0kg

250rpm

5.5 bar

Ø 12mm

18 litres/sec

BCT16/30VLDM

BCT20/50VL

10mm X 18mm

20mm X 50mm

20mm or 25mm

Variable

Ø25mm

Ø 110mm

0.5kg – 6.0kg

240rpm

5.5 bar

Ø 12mm

18 litres/sec

BCT20/50VLDM

BCT35/100VL

15mm X 30mm

35mm X 100mm

20mm or 25mm

Variable

Ø25mm or 55mm

Ø 170mm

0.5kg – 6.0kg

200rpm

5.5 bar

Ø 12mm

18 litres/sec

BCT50/150VL

25mm X 45mm

50mm X 150mm

20, 25 or 30mm

Variable

Ø25mm or 55mm

Ø 170mm

0.5kg – 6.0kg

150rpm

5.5 bar

Ø 12mm

26 litres/sec

![]() Designed for the fast, precision application of tape insulation systems

Designed for the fast, precision application of tape insulation systems

![]() Effortlessly tape up to 8 times faster than traditional methods

Effortlessly tape up to 8 times faster than traditional methods

![]() Simultaneously apply 2 layers of tape

Simultaneously apply 2 layers of tape

![]() Apply tape in both directions

Apply tape in both directions

![]() Easy to use

Easy to use

![]() Variable tape overlap

Variable tape overlap

![]() A wide variety of tapes can be used

A wide variety of tapes can be used

![]() Pneumatically driven – No complex electrical systems

Pneumatically driven – No complex electrical systems

|

BCT’S with Interleave

|

BCT 16/30VL – INT

|

BCT 20/50VL – INT

|

|---|---|---|

| Capacity: Cross Section of Conductor to be taped (max/min) |

5mm x 10mm

16mm x30mm |

10mm x 18mm

20mm x 50mm |

| Tape Width |

15mm or 20mm

|

20mm or 25mm

|

| Lap |

Variable

|

Variable

|

| Tape Spool – Core |

Ø 25mm

|

Ø 25mm

|

| Tape Spool – Outside Diameter |

Ø 80mm or 90mm

|

Ø 110mm

|

| Taping Tension |

0.5kg – 6kg

|

0.5kg – 6kg

|

| Taping Speed |

250rpm

|

240rpm

|

| Air Supply |

5.5 Bar

|

5.5 Bar

|

|

Recommended Min Bore |

Ø 12mm

|

Ø 12mm

|

| Free Air Use at Full Speed |

18 litres / sec

|

18 litres / sec

|

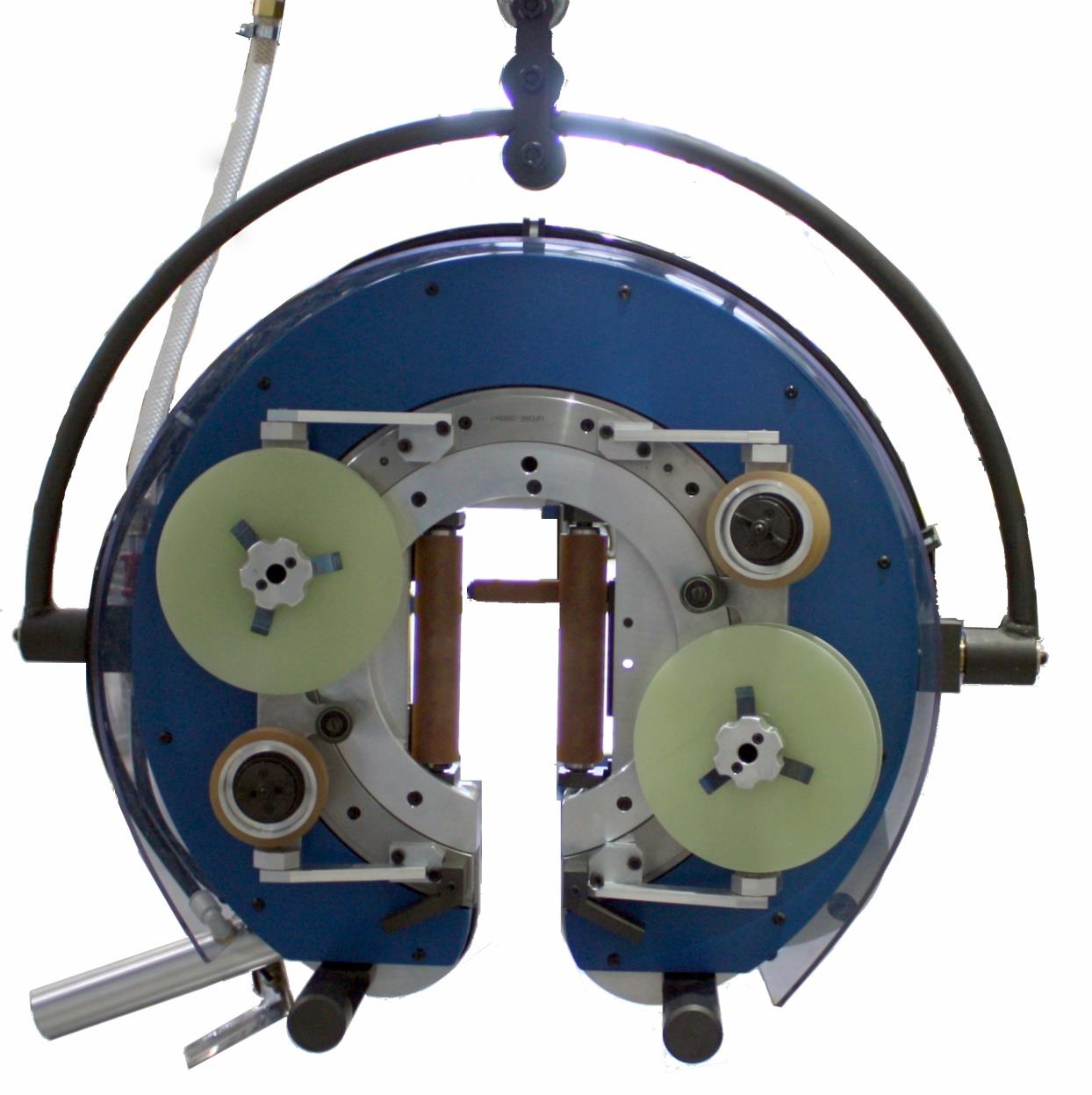

BCT coil taping machines are in service worldwide. Quality of tape application is assured by the powered drive roller and traverse reversing gearbox arrangement guaranteeing consistent tape overlap. Both the tape overlap and tape tension settings are variable and easily adjusted by the operator if required. The BCT taping machines are capable of simultaneously applying 2 layers of tape. Interleave tape collection can be accommodated if required.

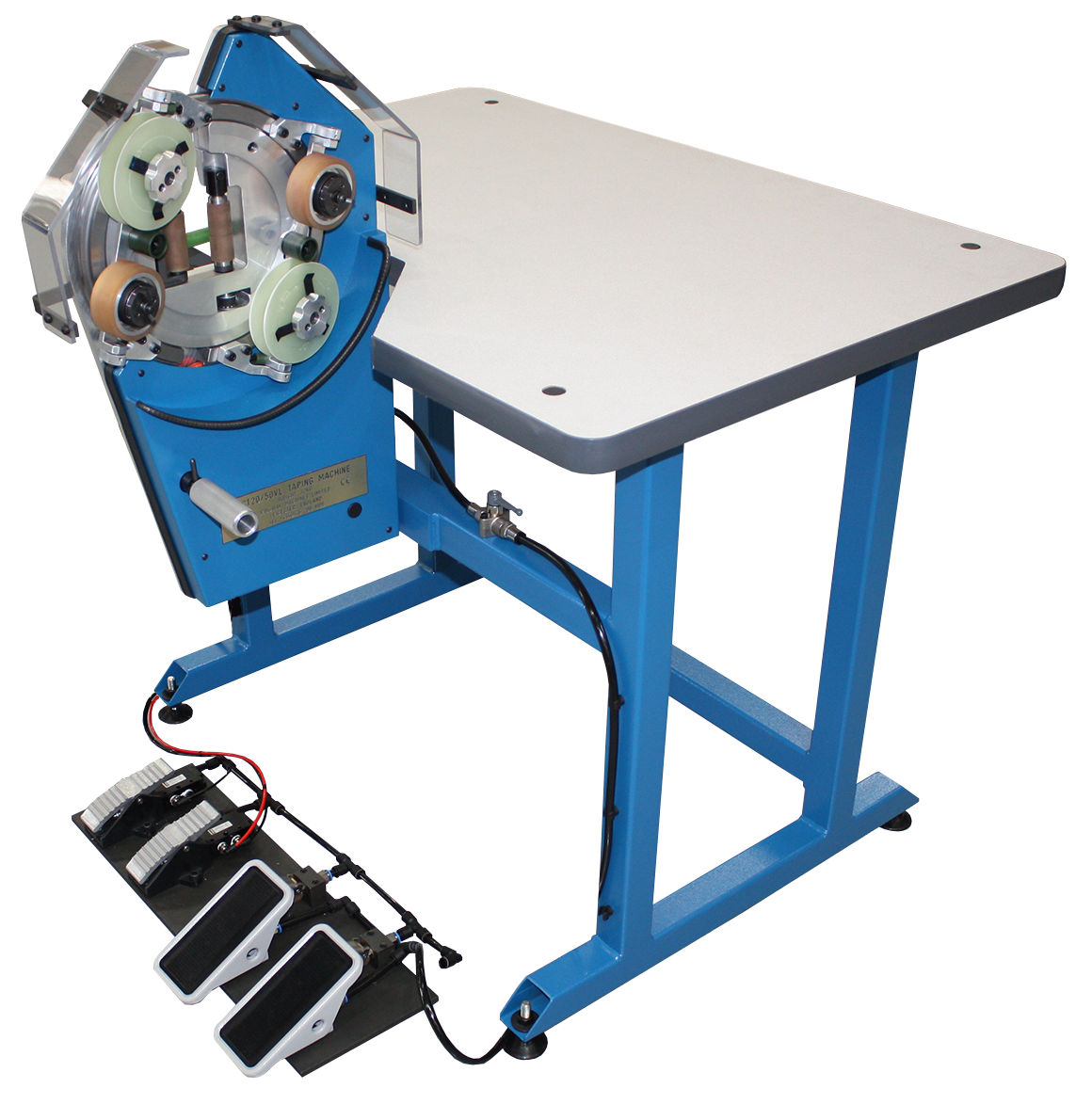

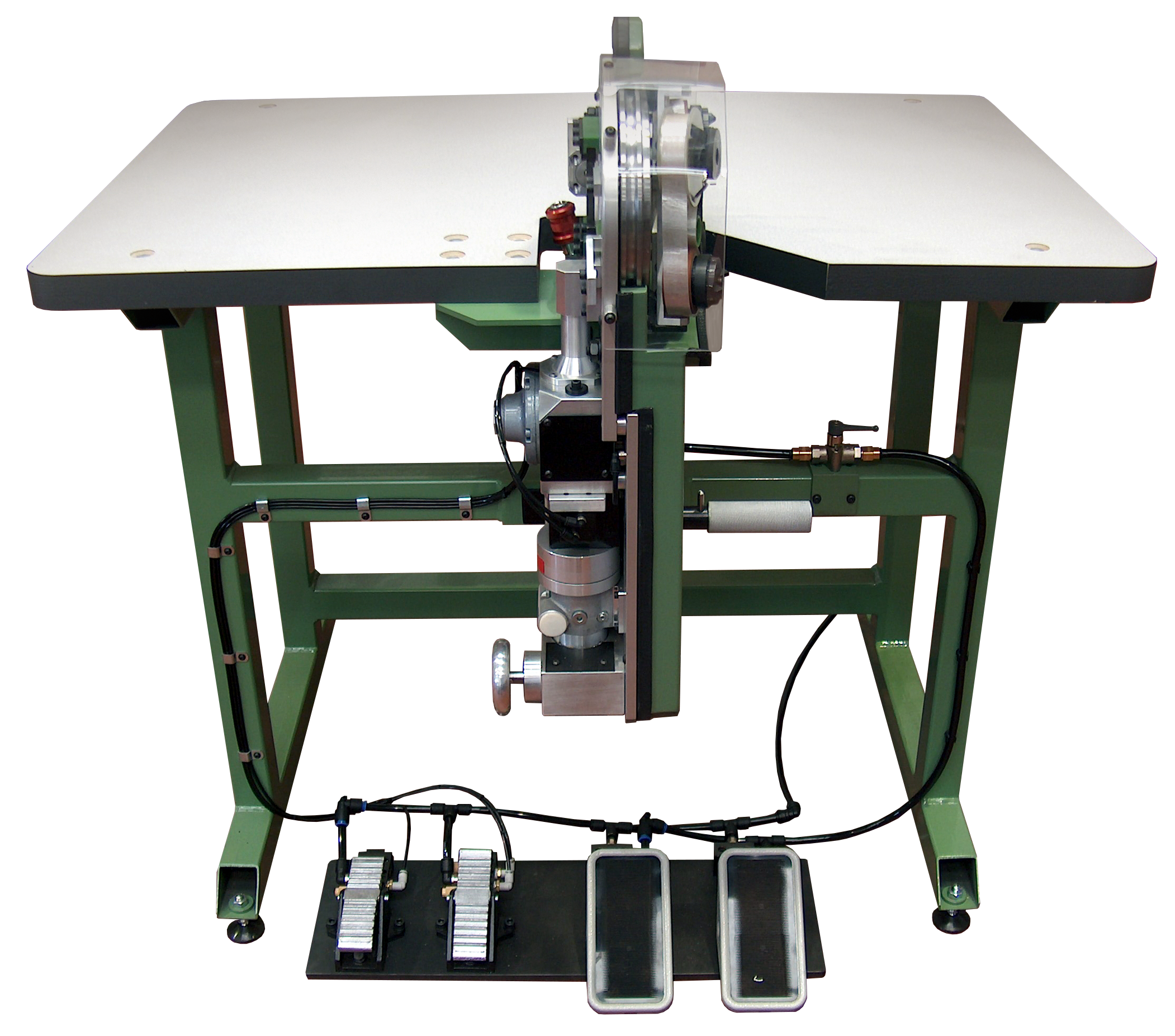

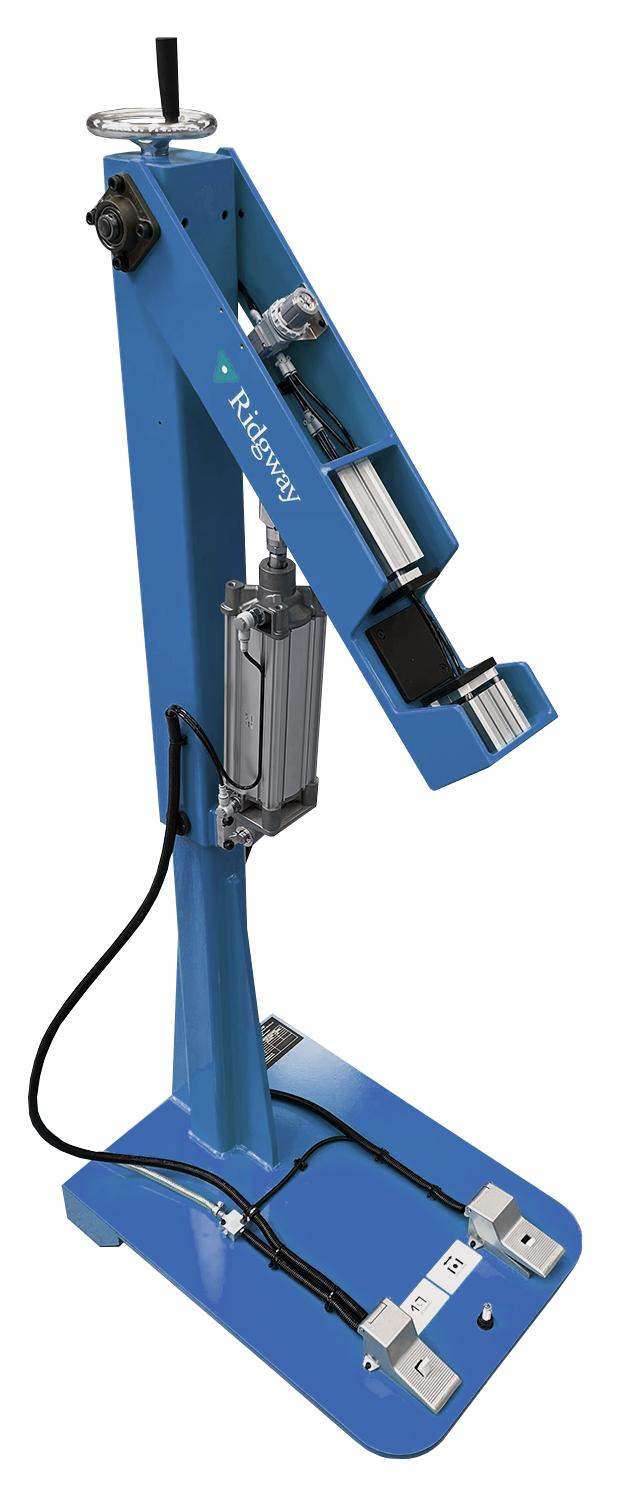

BCTVLDM – Bench Mounted Taping Machines

The BCT coil taping machine is available in a convenient bench mounted configuration. This provides a self-contained and cost effective solution for improving the productivity and quality of manually operated coil taping lines. The BCT Bench machine is ideal for taping smaller and open coils and bars, for applications such as motor and generator stators. Two layers can be applied simultaneously and the BCT tapes in both directions.

The machine is pneumatically operated, by a series of pneumatic foot pedals that control the clamp facility, traverse direction and taping speed, at speeds up to 250 rpm with no electrical power required.

![]() BCT is easily removed from the workbench to allow gantry suspension

BCT is easily removed from the workbench to allow gantry suspension

![]() Operation of the BCT bench models is via foot pedals

Operation of the BCT bench models is via foot pedals

|

Bench-Mounted BCT Model

|

BCT 16/30VLDM

|

BCT 20/50VLDM

|

|---|---|---|

| Capacity: Cross Section of Conductor to be taped (max/min) |

16mm x 30mm

5mm x10mm |

20mm x 50mm

10mm x 18mm |

| Tape Width |

15mm or 20mm

|

20mm or 25mm

|

| Lap |

Variable

|

Variable

|

| Tape Spool – Core |

Ø 25mm

|

Ø 25mm

|

| Tape Spool – Outside Diameter |

Ø 80mm or 90mm

|

Ø 110mm

|

| Taping Speed |

250 rpm max

|

240 rpm max

|

| Distance Between Coil Legs for Access |

115mm min

|

200mm min

|

| Air Supply |

5.5 Bar

|

5.5 Bar

|

|

Recommended Min Bore |

Ø 12mm

|

Ø 12mm

|

| Free Air Use at Full Speed |

18 litres / sec

|

18 litres / sec

|

| Bench Size | W 106cm x D 72cm x H 84cm | |

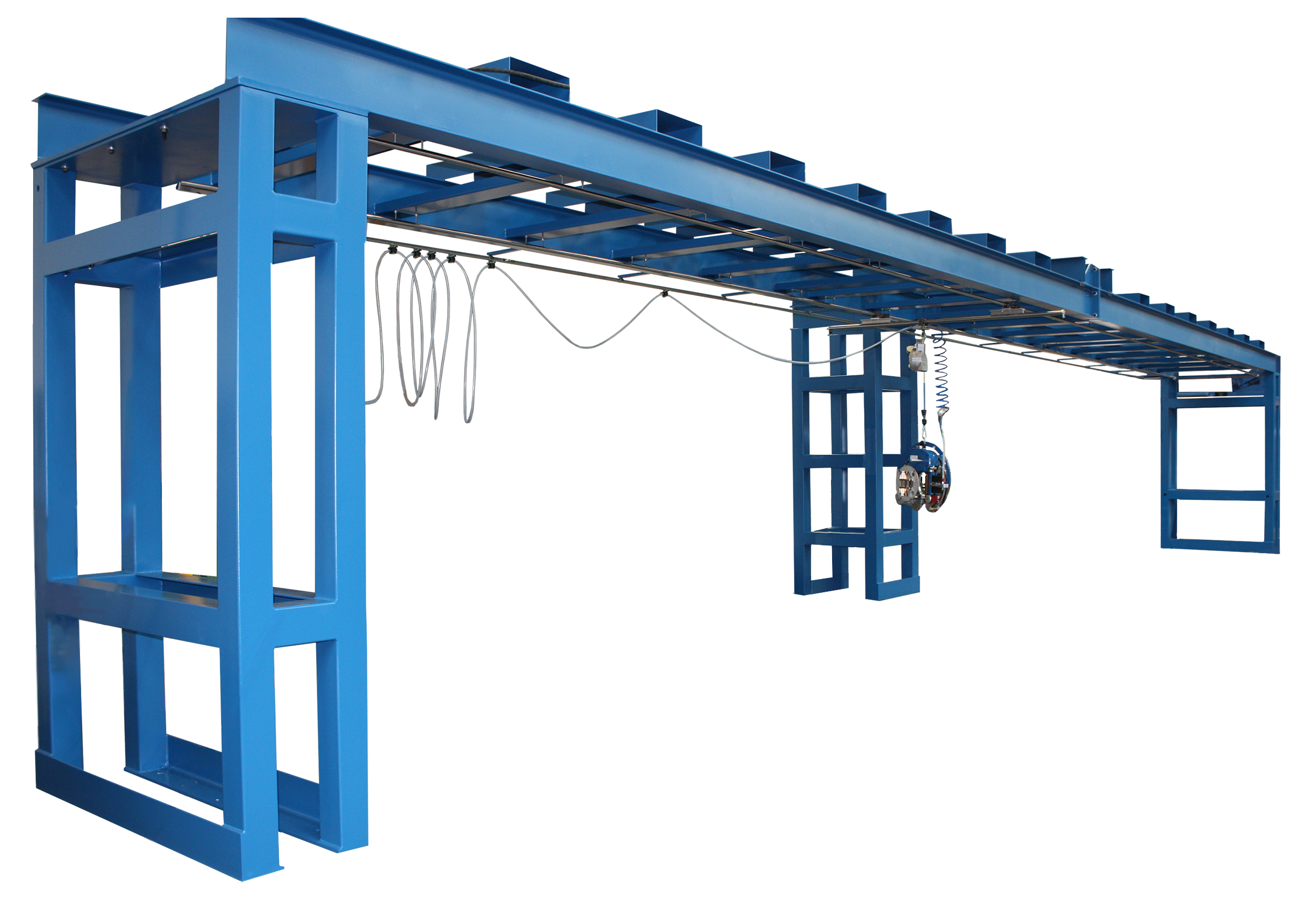

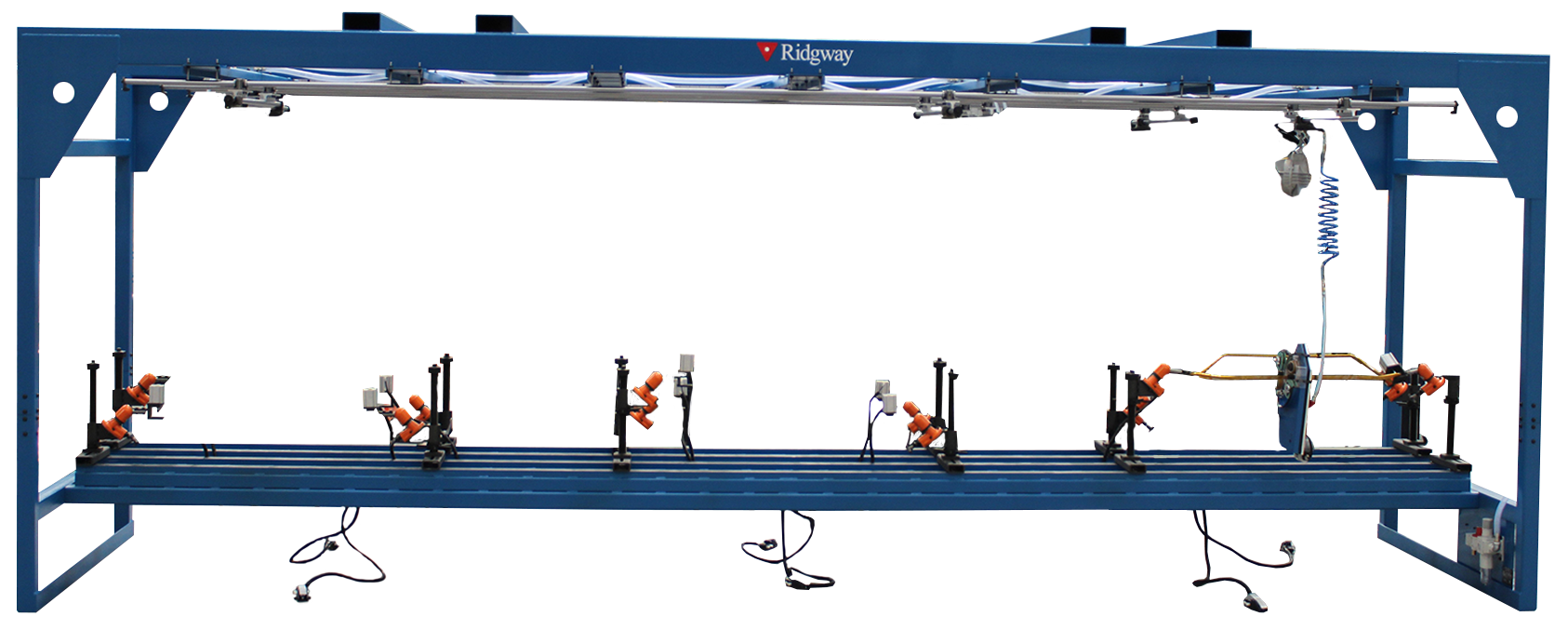

BCT Coil Handling Equipment

Increase your production effectiveness by complementing the range of BCT taping machines with Ridgway’s selection of dedicated handling equipment.

Used to provide fast, accurate and consistent methods of Operator guided tape application with virtually no preparation or set up time required.

![]() Designed as a workstation to weightlessly suspend BCT taping machines

Designed as a workstation to weightlessly suspend BCT taping machines

![]() The gantry range accommodates the CTU coil handling systems

The gantry range accommodates the CTU coil handling systems

![]() A free running carriage mounted to linear rails ensures smooth lateral motion of the taping head

A free running carriage mounted to linear rails ensures smooth lateral motion of the taping head

![]() Multiple carriages can be added to allow a variety of taping machines to be used

Multiple carriages can be added to allow a variety of taping machines to be used

![]() Quick and easy connection of the taping machine to the pneumatic circuit

Quick and easy connection of the taping machine to the pneumatic circuit

![]() Manufactured in a range of sizes

Manufactured in a range of sizes

COIL TURNOVER UNIT 2500

Gantry Required

3.5m

Max Coil Length

2500mm

COIL TURNOVER UNIT 3000

Gantry Required

4.0m

Max Coil Length

3000mm

COIL TURNOVER UNIT 4000

Gantry Required

5.0m

Max Coil Length

4000mm

COIL TURNOVER UNIT 5000

Gantry Required

6.0m

Max Coil Length

5000mm

![]() Designed to provide a complete, flexible and easy to operate coil handling solution

Designed to provide a complete, flexible and easy to operate coil handling solution

![]() Only one set up required to tape both coil sides

Only one set up required to tape both coil sides

![]() Coil rotation and work height adjustment easily achieved

Coil rotation and work height adjustment easily achieved

![]() Coil securely held by two pneumatic clamps actuated via a foot pedal

Coil securely held by two pneumatic clamps actuated via a foot pedal

![]() Adjustable mechanical stops ensure repeat rotational positioning

Adjustable mechanical stops ensure repeat rotational positioning

![]() CTU mounted coil supports available

CTU mounted coil supports available

![]() Rear coil supports and retractable front coil supports available

Rear coil supports and retractable front coil supports available

CTU Mounted Coil Supports

Used in conjunction with the CTU,

additional rail mounted coil supports can be provided depending on the width or

geometry of the coil design.

Rear Support

Free standing rear support designed

for quick and easy operation.

Manual vertical adjustment.

Retractable Front Supports

Comprising of an air cylinder with an adjustable soft top, enabling the desired work height to be achieved. Cylinder up and down movement is actuated via a foot pedal.

Turn Taping Gantry

The unit is used as a suspension gantry to hold a ‘BCT’ taping machine to apply a variety of insulation tapes to a conductor prior to coil winding.

The taping machine is suspended from a linear rail mounted to the underneath of the gantry overhead beam.

The gantry should be positioned such that the taping machines can be used as close to the loop winding pins as possible without causing damage to either machine when the winding beam is rotated.

![]() Designed as a workstation to weightlessly suspend BCT taping machines

Designed as a workstation to weightlessly suspend BCT taping machines

![]() Flexible design to fit available space

Flexible design to fit available space

![]() A free-running carriage mounted to linear rails nensures smooth lateral motion of the taping head

A free-running carriage mounted to linear rails nensures smooth lateral motion of the taping head

![]() Space saving design

Space saving design

![]() Quick and easy connection of the taping machine to the pneumatic circuit

Quick and easy connection of the taping machine to the pneumatic circuit

Bespoke Gantries

For larger projects Ridgway can design and manufacture bespoke gantry systems.

Free standing supports can be utilised to complement the bespoke gantries.

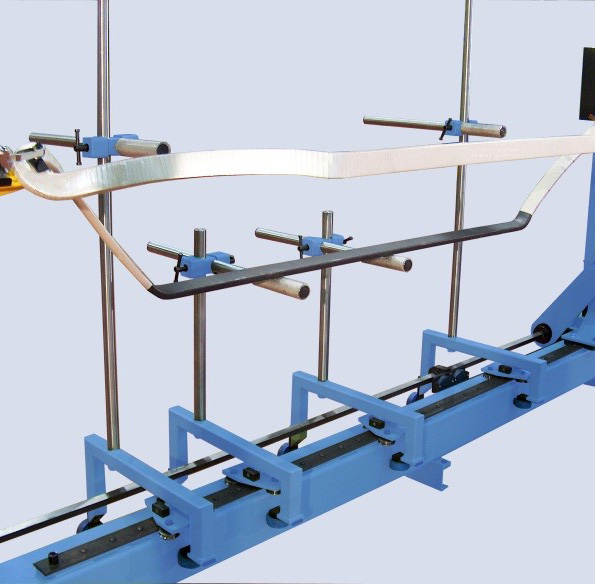

Portable Holding Fixtures

To enable continuous taping, the clamping arms of the fixtures can be lowered to enable free passage of the taping machine. Foot pedals on the base of the fixtures will enable the clamp to open and close and to raise and lower the clamping arm.

![]() The clamps are free standing and are height adjustable

The clamps are free standing and are height adjustable

![]() Clamping pressure is adjustable

Clamping pressure is adjustable

![]() Pneumatic operation is controlled manually by the operator via a foot pedal

Pneumatic operation is controlled manually by the operator via a foot pedal

Bench Support Gantry

A simple coil support gantry with

pneumatic coil clamping workstations. Can be configured from 1 to 6 individual operator workstations. Multiple BCT coil taping machines can be suspended from free running carriages mounted on

overhead linear rails. Virtually no

preparation or set up time required. Clamping of the coil is via pneumatic clamps operated by a foot pedal.

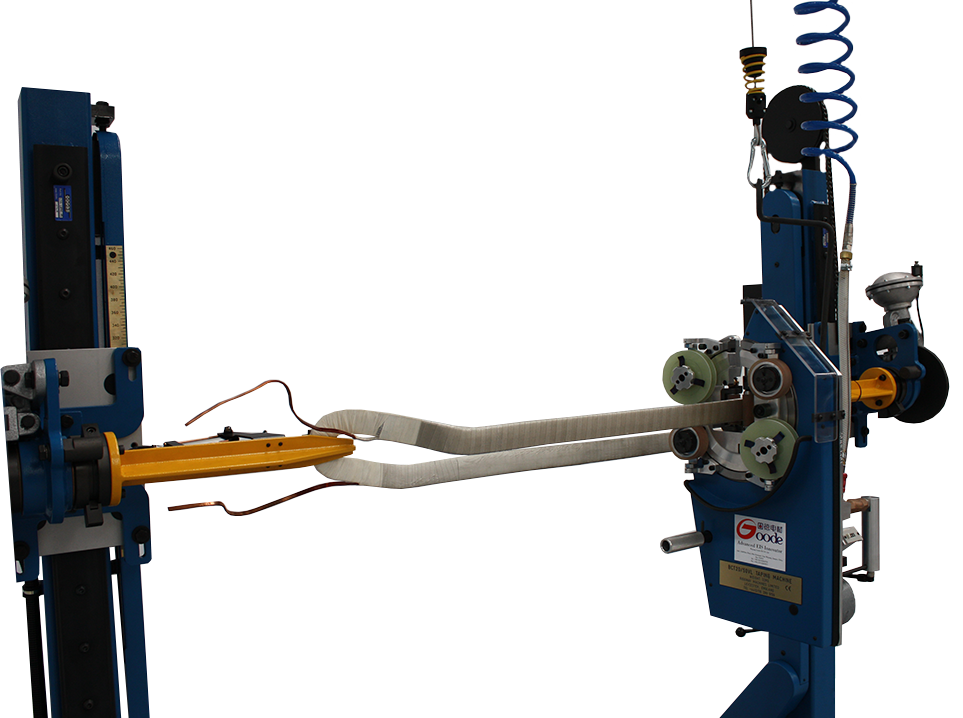

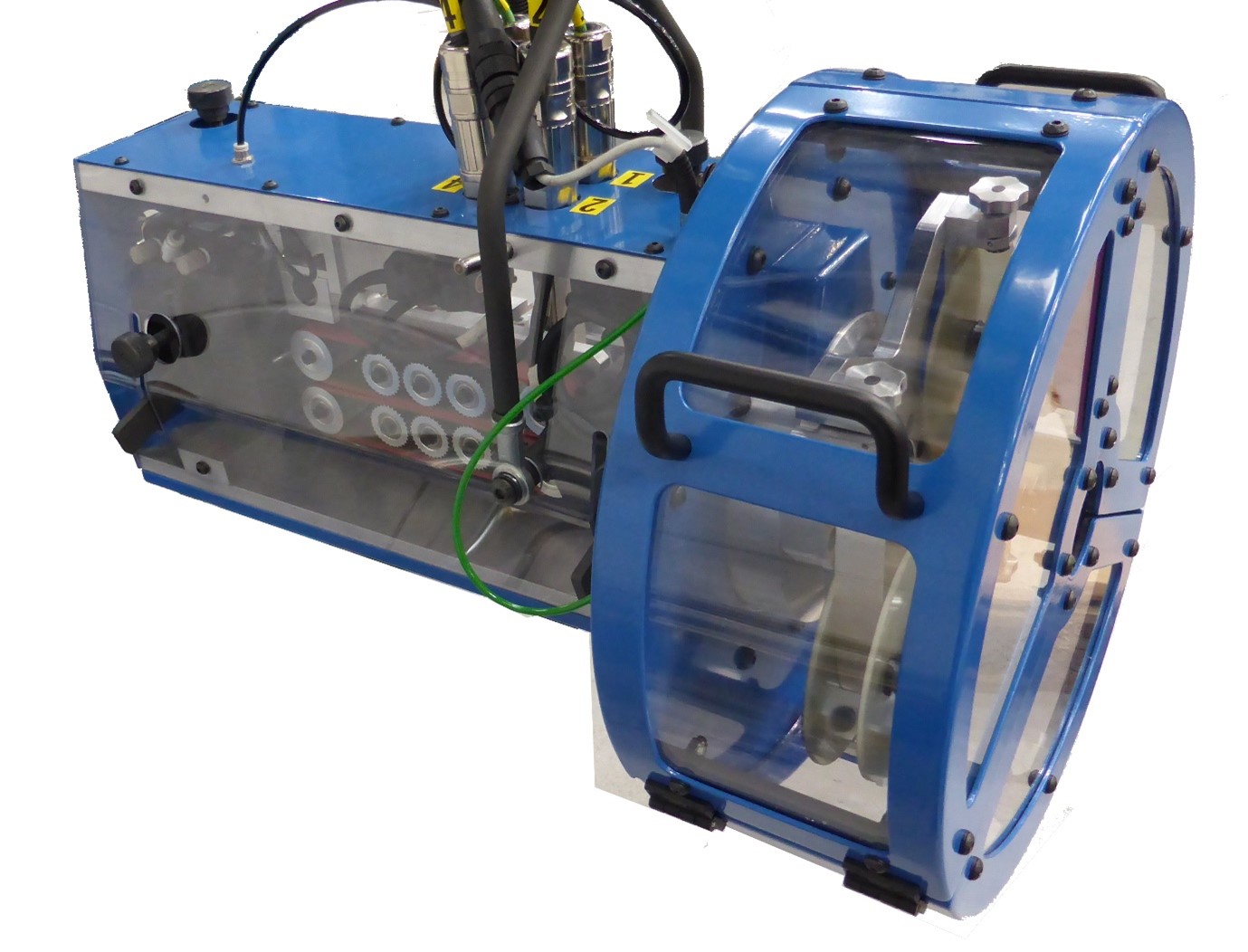

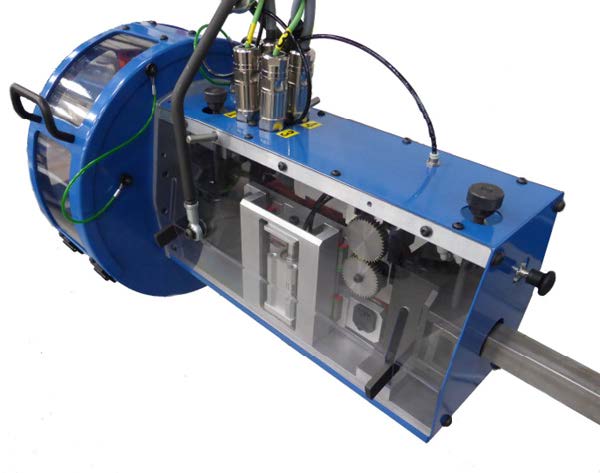

STT - Squirrel Turn Taper

The STT offers a simple solution to dramatically reduce the overall coil manufacturing time of turn taped coils. Designed for the efficient taping of multiple conductors as they pass between the drum stand, gathering box and loop winding beam during the loop winding process.

![]() Variable tape overlap

Variable tape overlap

![]() Simultaneously apply 2 layers of tape

Simultaneously apply 2 layers of tape

![]() Operation is via a control panel mounted on a pedestal.

Operation is via a control panel mounted on a pedestal.

Rotational and linear speeds are adjustable via potentiometers

The conductor stack is fed through the STT and centralised using roller boxes. The machine has guarding that is fitted with sensors. If the guard is open, it will prevent the machine from operating.

![]() The machine is driven by twin caterpillar belts, powered by a synchronised servo motor

The machine is driven by twin caterpillar belts, powered by a synchronised servo motor

![]() To ensure consistent adhesion to the

To ensure consistent adhesion to the

conductor stack, the machine is fitted with a pneumatic traction control system

![]() The STT is freely suspended from its own support gantry. Gantries are manufactured to match exact requirements

The STT is freely suspended from its own support gantry. Gantries are manufactured to match exact requirements

|

Capacity

|

20mm x 30mm

|

|---|---|

| Tape Width |

20mm

|

| Lap |

Variable

|

| Lap |

Variable

|

| Tape Spool – Core |

Ø 25mm

|

| Tape Spool – Outside Diameter |

Ø 80mm or 90mm

|