Coil Manufacturing

Ridgway Machines manufactures a full range of Coil Manufacturing Equipment, including Rotor Winders, Loop Winders and ancillary equipment such as Capstan Tension Units, Winding Beams Coil Pull-Out Machines and Drum Stands. Manufactured to high specifications and incorporate the latest safety features and fully programmable operator control.

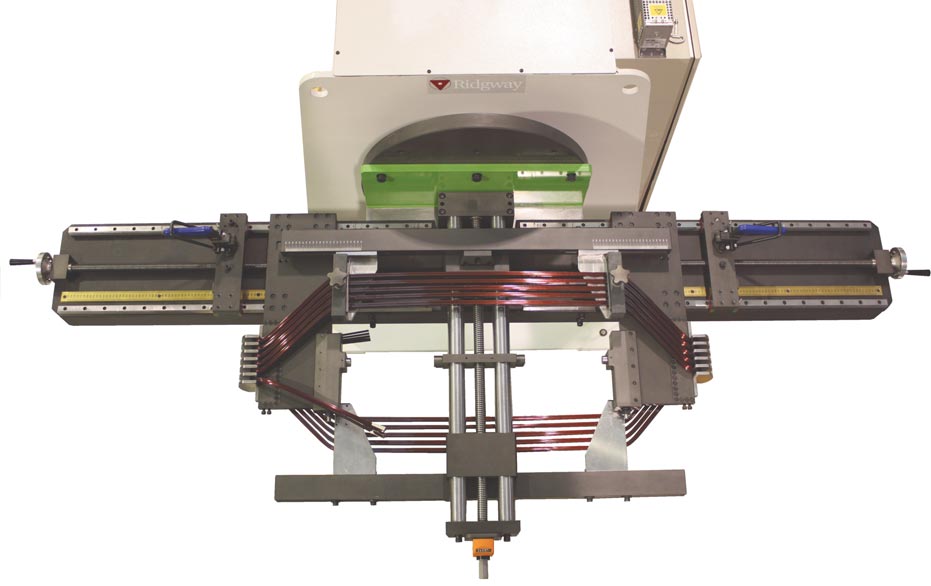

LWDS - Loop Winder Drum

The LWDS Loop Winder Drum Stand range is designed to compliment Ridgway’s range of loop winders during the loop winding process. A fabricated steel frame with cantilever drum shafts support the conductor drums. The number of drum positions can be configured to suit individual customer requirements.

![]() The drum shafts carry individual back tension brakes, comprising of a brake drum onto which a brake shoe operates.

The drum shafts carry individual back tension brakes, comprising of a brake drum onto which a brake shoe operates.

![]() Each drum shaft has individual tension adjustment. The tension adjustment is provided via a pneumatic cylinder connected to an individual lever valve with a pressure regulator and visual pressure gauge.

Each drum shaft has individual tension adjustment. The tension adjustment is provided via a pneumatic cylinder connected to an individual lever valve with a pressure regulator and visual pressure gauge.

Technical Specification

MODELS

LWDS2 | LWDS4 | LWDS6 | LWDS8 | LWDS10 | LWDS12 |

Max Drum Diameter

800mm

Max Drum Width

300mm

Weight Of Drum

150kg

Drum Configuration

LWDS2 – 2×1 | LWDS4 – 2×2 | LWDS6 2×3 | LWDS8 2×4 | LWDS10 2×5 | LWDS12 2×6|

Active drum tension control

Compared to the alternative of the LWDS friction braking, active tensioning offers a wear free solution with accurately controllable individual constant drum tensions.

Tension adjustment for each drum is provided via a HMI on the winder control panel. Tension range is 0 – 35kg per drum and is constant throughout the life of the drum.

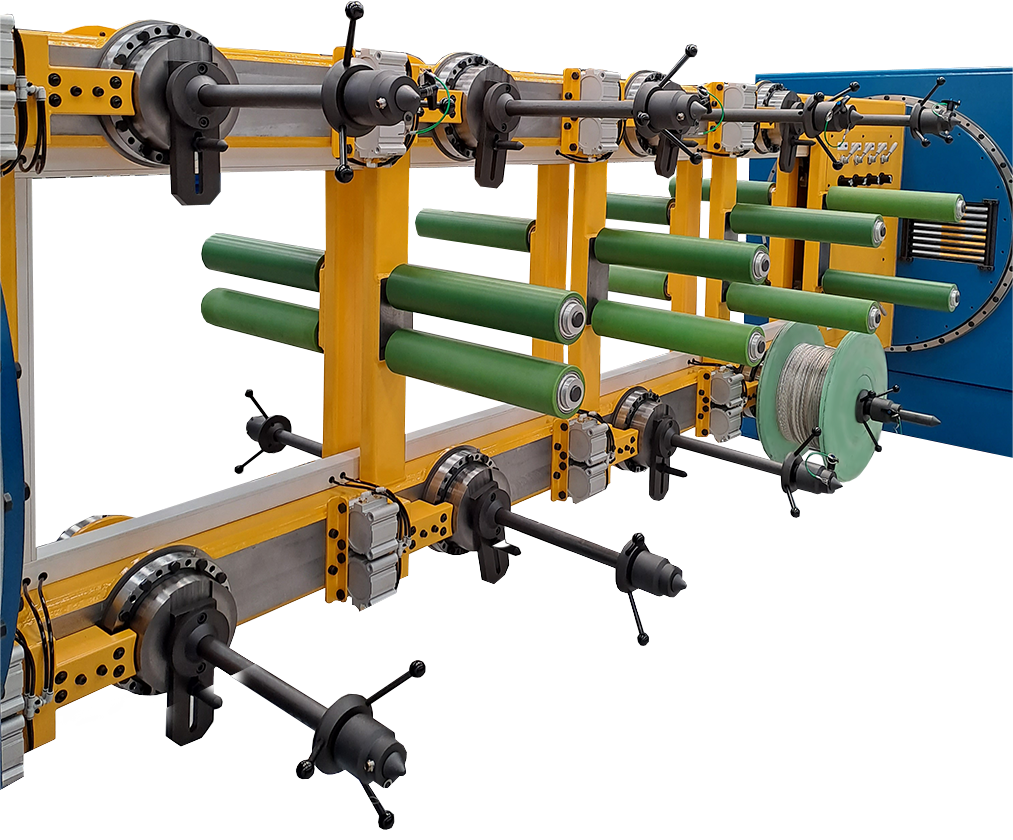

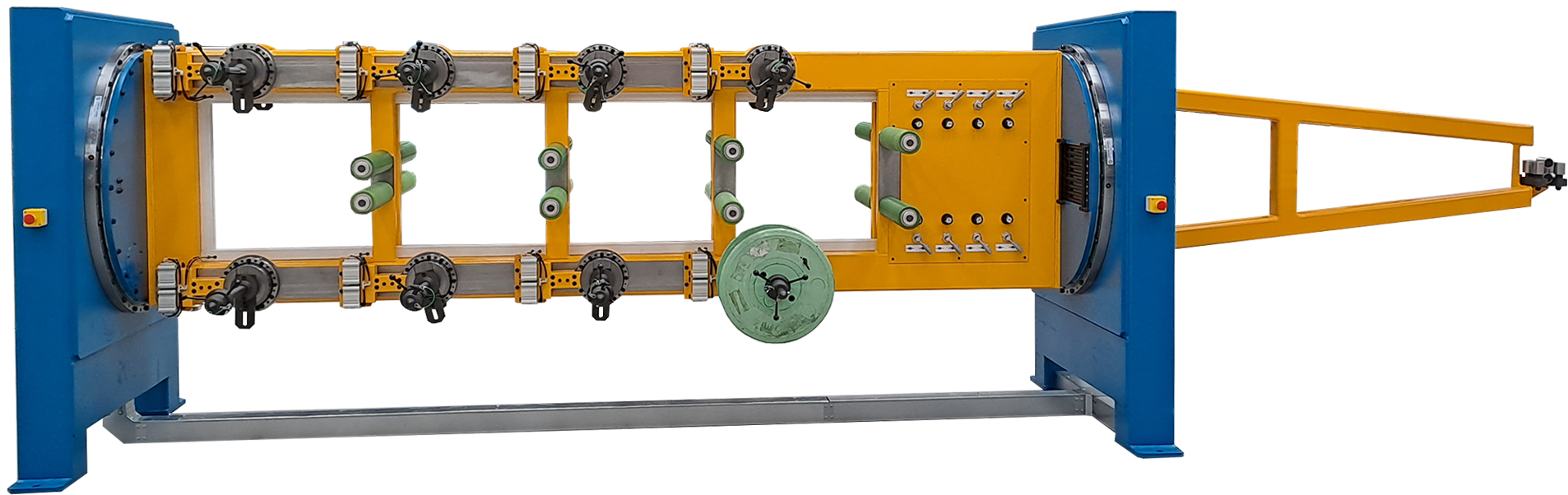

LWDS-R – Loop Winder Drum Stand

The LWDS-R Rotating Loop Winder Drum Stand range is designed to rotate 180 degrees to assist in end-winding transposition of looped coils during the loop winding process. The number of drum positions can be configured to suit individual customer requirements.

The drum shafts also carry the back tension brake, comprising of a brake drum onto which a brake shoe operates. Tension adjustment for each drum is provided via a cylinder connected to a lever valve and a pressure regulator. Each brake system can be switched on or off via the hand operated valve, with the tensions adjusted by the pressure regulator next to each hand valve, with a pressure gauge for reference.

The fabricated frame is fixed to a front and rear support structure. Each of these structures includes a bearing system – the rear system consists of a slewing ring arrangement to enable the drum frame to rotate 180 degrees. Rotation of the slewing ring is controlled via a motor and drive system that is operated from a control panel located adjacent to the drum stand. The system is designed to rotate 180 degrees in one direction then back again.

Technical Specification

Max Drum Diameter

800mm

Max Drum Width

300mm

Max Drum Weight

150 kg

Drum Shaft Diameter

Ø 32mm

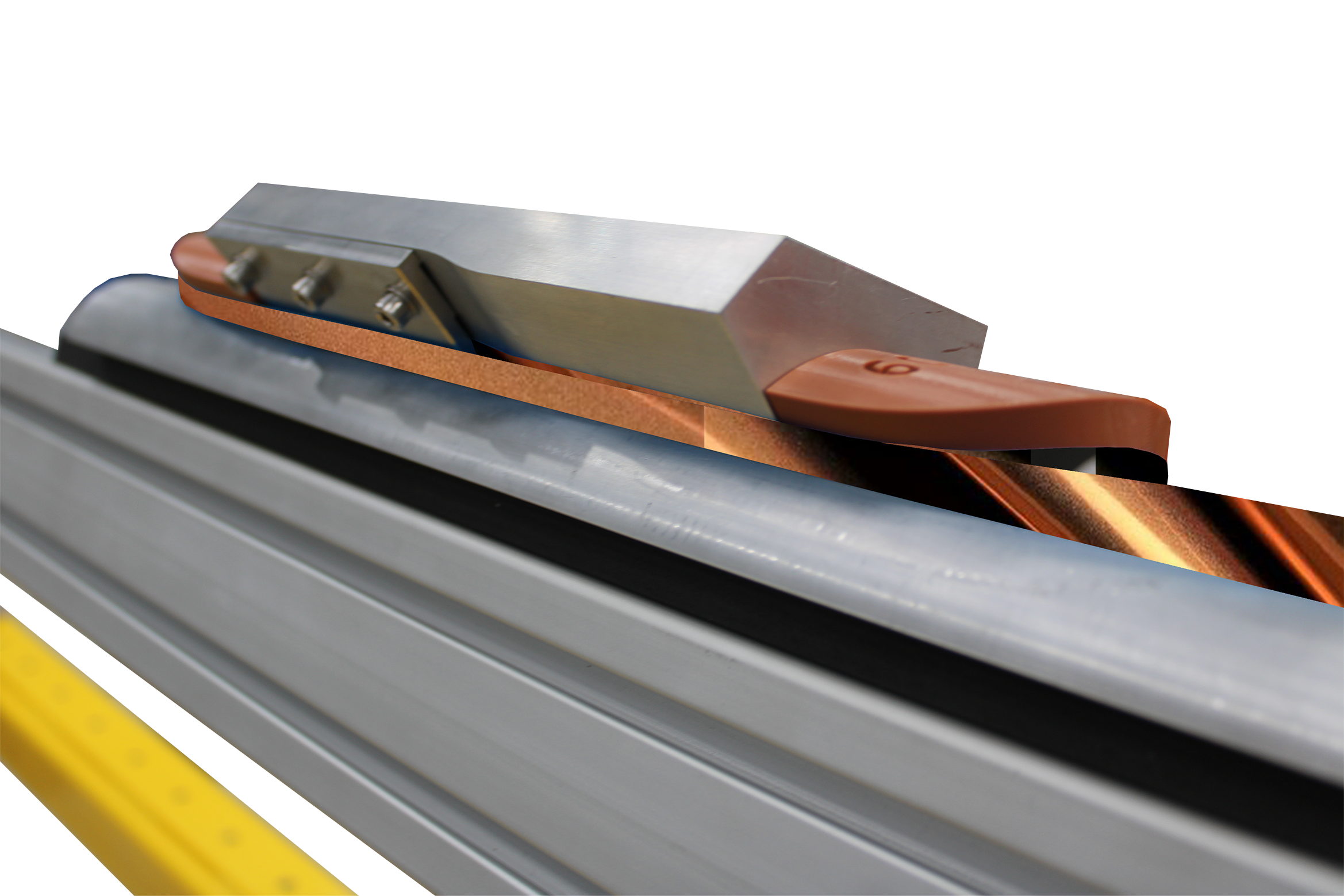

![]() Cantilevered drum shafts, each with twin bearing units. The drums are mounted to the drum shafts by means of tapered cones to accept a range of drum bore sizes.

Cantilevered drum shafts, each with twin bearing units. The drums are mounted to the drum shafts by means of tapered cones to accept a range of drum bore sizes.

![]() The drum shafts also carry the back tension brake, comprising of a brake drum onto which a brake shoe operates. Tension adjustment for each drum is provided via a cylinder connected to a lever valve and a pressure regulator.

The drum shafts also carry the back tension brake, comprising of a brake drum onto which a brake shoe operates. Tension adjustment for each drum is provided via a cylinder connected to a lever valve and a pressure regulator.

![]() Each brake system can be switched on or off via the hand operated valve, with the tensions adjusted by the pressure regulator next to each hand valve, with a pressure gauge for reference.

Each brake system can be switched on or off via the hand operated valve, with the tensions adjusted by the pressure regulator next to each hand valve, with a pressure gauge for reference.

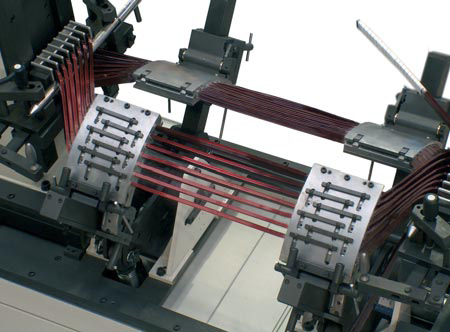

W-LMP - Loop Winder

For a versatile and cost effective solution to suit your loop winding requirements.

Sturdy construction, free standing control panel and digital turns counter are key features of our loop winding solutions.

Technical Specification

Model Loop Winding Beam

LWWB 1500 | 2000 | 3000 | 5000

Length of Loop

LWWB min 350mm –

1500mm | 2000mm | 3000mm | 5000mm

Pin Diameter

min 12mm – max To suit cutomer requirements

Conductor Width

min 3mm – max 50mm

Lead Clamp

YES

D-Loop Tooling

Optional

![]() Vector motor drive

Vector motor drive

The W-LMP incorporates the latest vector drive technology. A variable speed geared motor directly drives the main spindle, providing a high torque capability with soft start.

![]() Quick release tooling

Quick release tooling

Operator friendly solutions for both the

conductor clamping and winding pin assemblies. Optional “D” loop tooling also available.

![]() Operator controls

Operator controls

Easy to operate control panel for the adjustment of winding speed and direction of rotation. Large digital turns counter with reset capability.

![]() Guides

Guides

Free standing, adjustable conductor guides are incorporated into the winding line as standard.

![]() Quick, accurate set up

Quick, accurate set up

All winding beams incorporate a pair of fully adjustable winding pins and a conductor

clamping arrangement. For reference, scales are fitted to the winding beam, ensuring fast and accurate set-ups can be achieved.

![]() Anti-run back

Anti-run back

The winder incorporates an electrically released brake, preventing run back and

eliminating tension loss during stopping and starting.

![]() Operator platforms

Operator platforms

Optional work platforms are available, designed to ensure a safe working environment for your operators.

W-LAP - Loop Winder

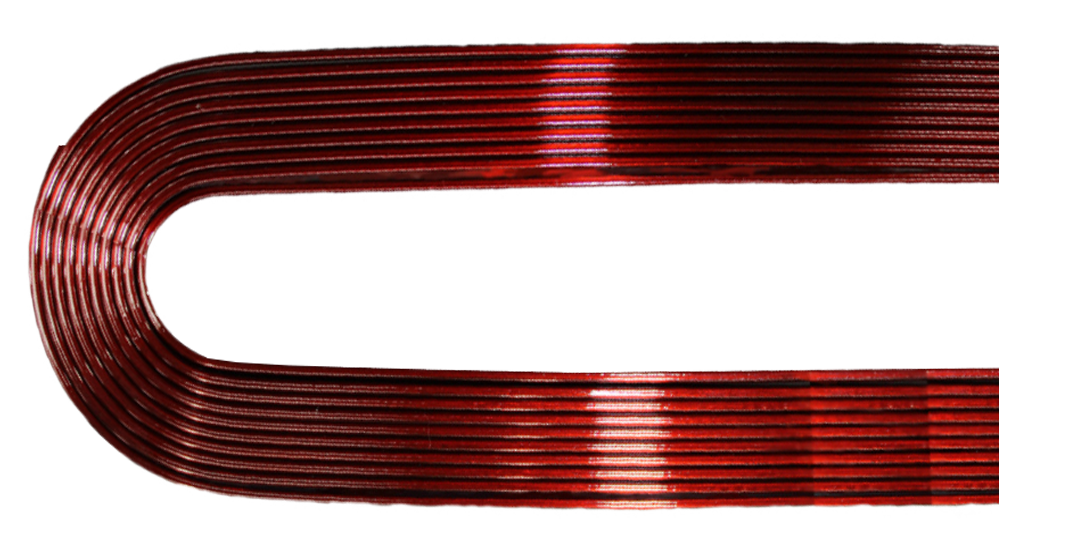

The range of Ridgway’s W-LAP Loop Winders are used to manufacture precise multi turn looped coils.

Automatic programmable pin positioning, combined with conductor gathering and guidance systems ensure precise and consistent quality.

Technical Specification

Model

W-LAP 1500 | 2000 | 3000 | 5000 | 7000

Maximum Torque

W-LAP 1500Nm | 2000Nm | 3000Nm | 5000Nm | 7000Nm

Speed Range

W-LAP 1500 – 0 to 25 rpm

W-LAP 2000 | 3000 | 5000 – 0-20 rpm

W-LAP 7000 – 0-15 rpm

![]() Programmable Winding

Programmable Winding

Automatic winding pin positioning and end of cycle release.

![]() Tooling

Tooling

Optional D-Loop tooling available

![]() Improved quality

Improved quality

Fast, accurate and consistent winding of looped coils.

![]() Anti-run back

Anti-run back

The winder incorporates an electrically released brake, preventing run back and eliminating tension loss during stopping and starting.

![]() Quick release tooling

Quick release tooling

All winding beams incorporate a pair of fully adjustable winding pins and a conductor

clamping arrangement. For reference, scales are fitted to the winding beam, ensuring fast and accurate set-ups can be achieved

![]() Conductor gathering and guidance

Conductor gathering and guidance

Conductor gathering and guidance systems ensure precise and consistent quality.

![]() Servo motor drives

Servo motor drives

The W-LAP incorporates the latest servo drive technology.

![]() Operator HMI control

Operator HMI control

Easy to operate control panel for the adjustment of loop length, winding speed. Other functions include the ability to set and count the number of turns per coil and the quantity of coils per set. Coil winding details can also be stored within the control system for future use.

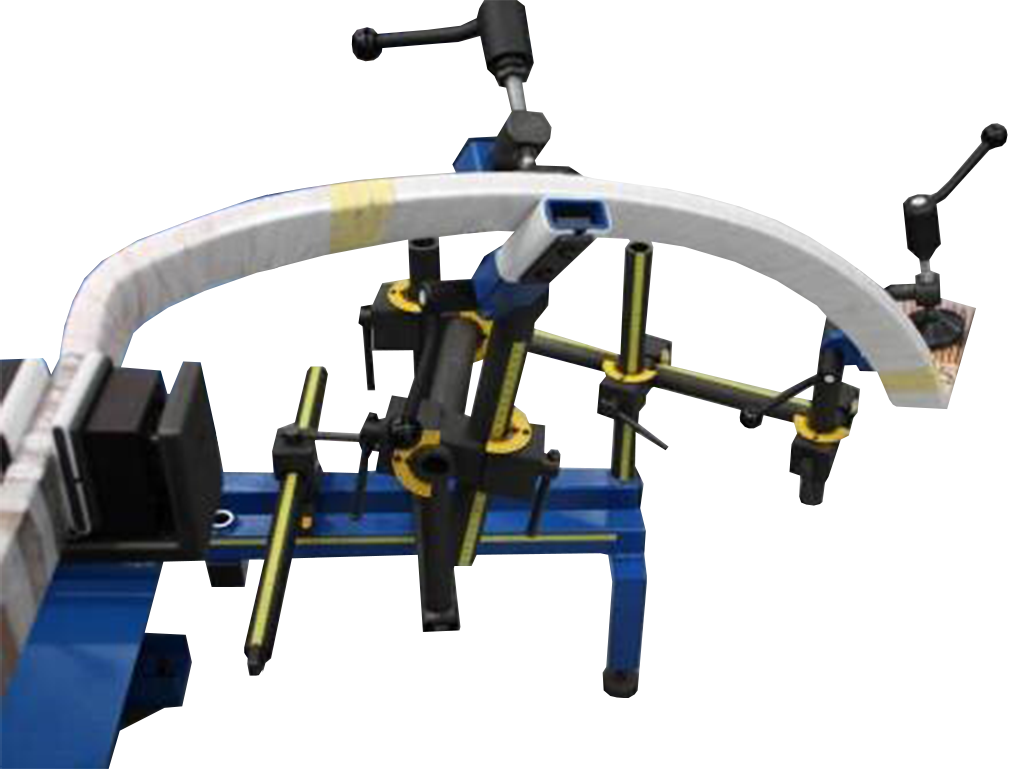

W-3DW - 3D Multi - Axis Winder

Designed for organisations that need complex 3D-shaped coils for various applications.

The Ridgway Multi-Axis Coil Winding Machine meets these needs by winding coils in

multiple planes.

The operator control unit features a wireless controller linked to the machinery control system, allowing the operator to safely approach the coil winding area.

Technical Specification - Pay-Off Drum Stand

Max Drum Diameter

600mm

Max Drum Width (Height)

350mm

Max Drum Weight

75kg

Max Pay-Off Speed

10rpm

Conductor Tension

50N to 500N +/-10%

Technical Specification - Coil Winding Machine

Max Beam Rotation Speed

4rpm

Max Beam Torque

750Nm

Max Beam Spindle Rotation Speed

4rpm

Max Beam Spindle Torque

650Nm

Max Conductor Size

30mm H x 10mm W

Max Height Movement (Y AXIS)

750mm

Max Side to Side Movement (X AXIS)

2600mm

Max Conductor Rotation (C AXIS)

+/-120 ° from datum axis

Max Linear Movement Speed

20mm per second

Max Conductor Rotation Speed

30 ° per second

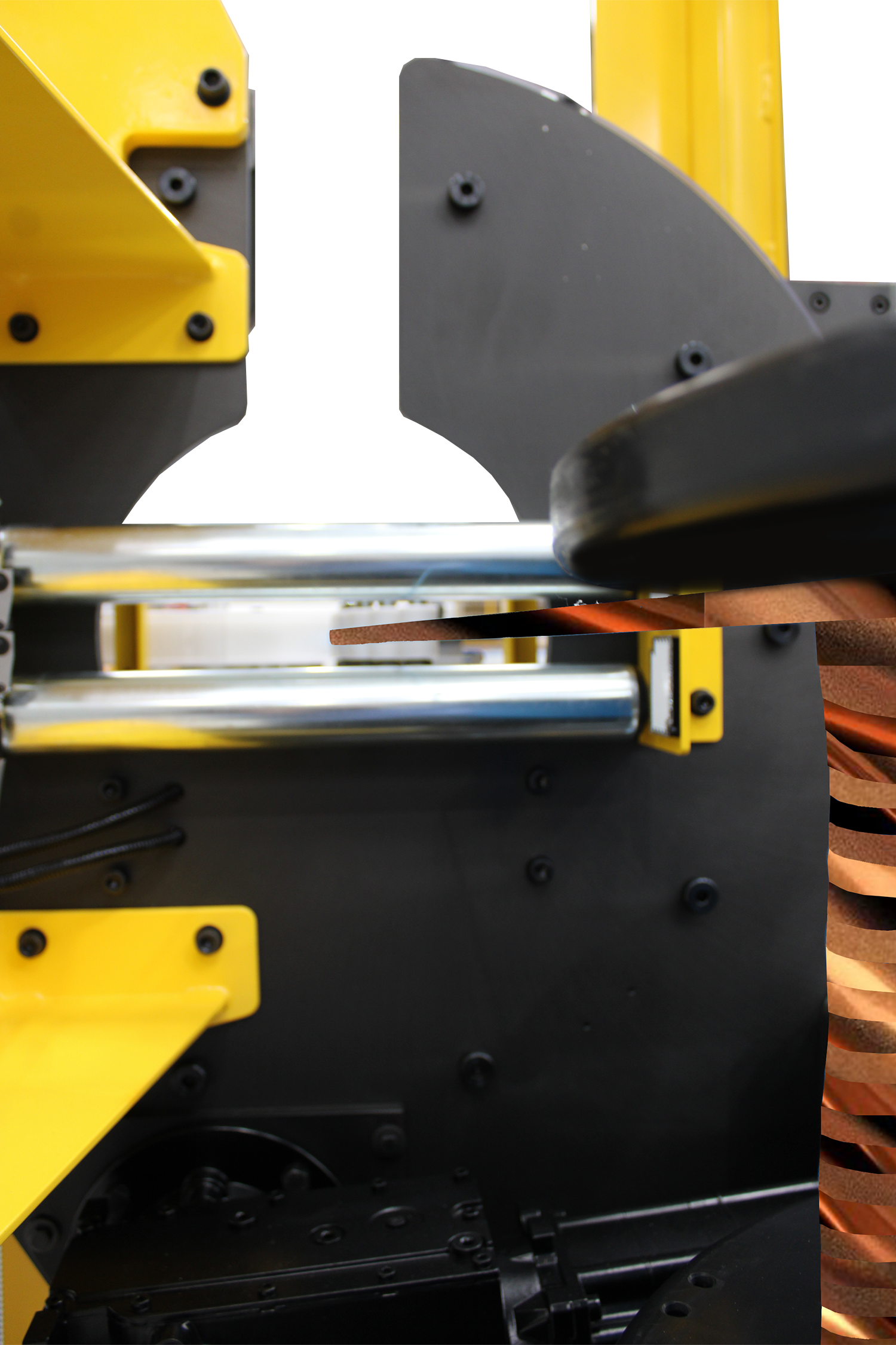

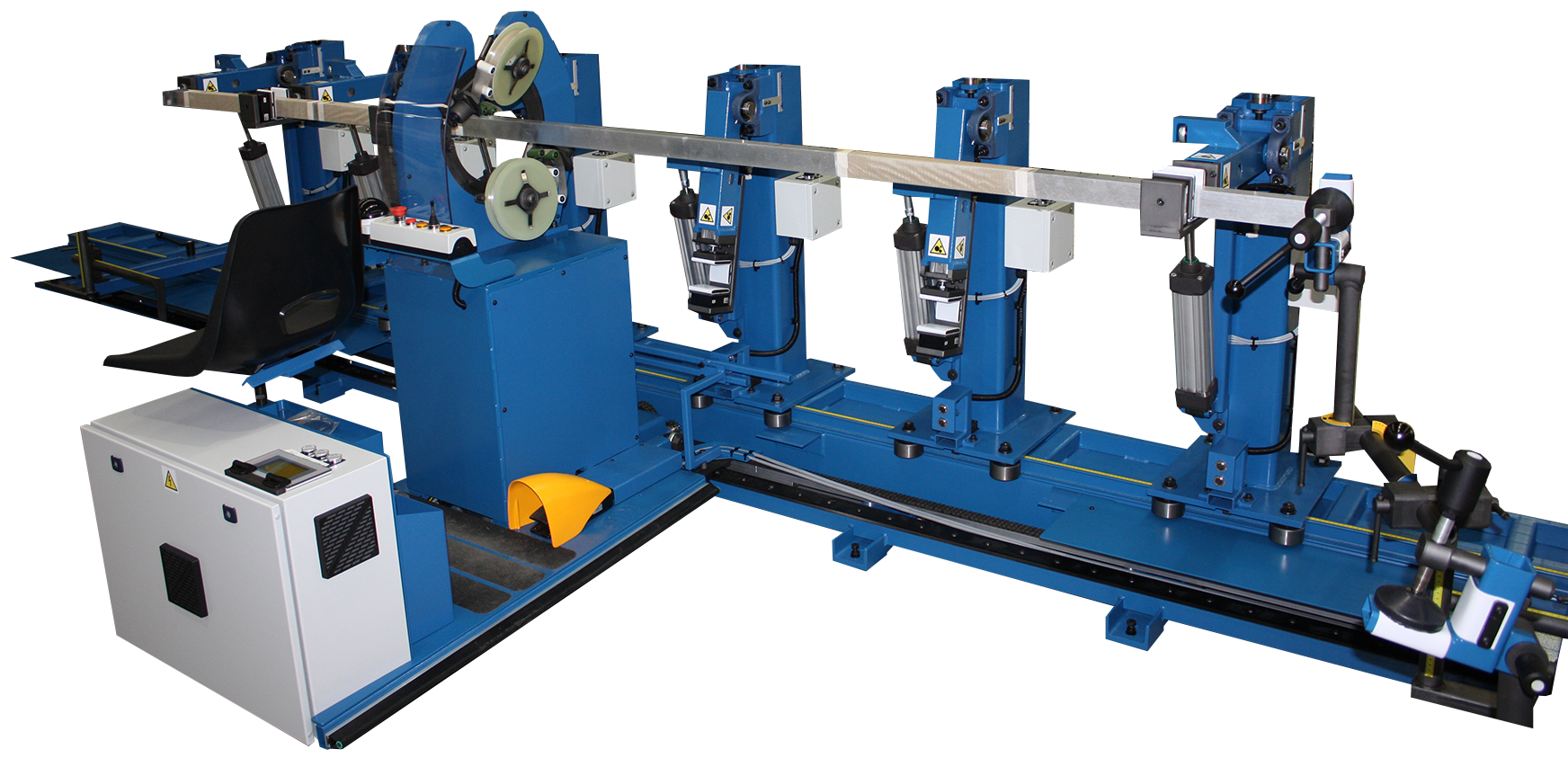

W-MAW - Multi-Axis Winder

Improve production effectiveness by utilizing the Ridgway W-MAW. Incorporating a programmable multi-axis winding machine with active drum tensioning and conductor guidance systems, the equipment ensures fast, consistent and high quality production of complex shaped stator coils.

Technical Specification

Loop Winder

Maximum torque

Up to 9000 Nm

Speed range

0 to 10 rpm

Fully programmable

Winding Beam

Maximum length

Up to 2.5 metres

Servo controlled beam positioning

Servo controlled tool rotation

![]() Main spindle drive

Main spindle drive

The W-MAW incorporates the latest servo drive technology. A variable speed geared motor directly drives the main spindle, providing a high torque capability throughout the speed range.

![]() Multi-axis winding beam

Multi-axis winding beam

Encoder feedback ensures accurate positional control of the winding beam. An additional servo driven gearbox, mounted directly to the winding beam also provides rotational movement of the coil tooling.

![]() Conductor guidance

Conductor guidance

The W-MAW incorporates the latest servo drive technology. A variable speed geared motor directly drives the main spindle, providing a high torque capability throughout the speed range.

![]() Operator control

Operator control

Conductor guidance is provided via a free standing guide post to ensure vertical, horizontal and angular positioning is maintained. Additional servo controlled conductor guidance can also be fitted to the coil tooling if required.

W-RHD - Rotor Winding Machine

For a complete solution to enable the fast and effective winding of rotor pole coils.

Technical Specification

Maximum torque

Up to 10000 Nm

Speed range

0 to 10 rpm

Maximum rotor weight

W-RHD5000 – up to 5000kg

W-RHD10000 – up to 10000kg

Faceplate centre height

1300mm (other heights available)

Ridgway Capstan Tension Unit

Variable tension control

Adjustable guide rollers

Pneumatic brake override

![]() Geared servo drive system

Geared servo drive system

The W-RHD incorporates the latest servo drive technology. A variable speed geared motor

directly drives the main spindle, providing a high torque capability throughout the speed range.

![]() Pneumatic holding brake

Pneumatic holding brake

The spindle is fitted with a pneumatic holding brake to ensure a positive stop.

![]() Operator controls

Operator controls

The main control panel used to vary speed and direction of rotation is mounted on a

free-standing pedestal giving greater operator flexibility.

![]() Indexing

Indexing

Conductor guidance is provided via a free standing guide post to ensure vertical, horizontal and angular positioning is maintained. Additional servo controlled conductor guidance can also be fitted to the coil tooling if required.

![]() Tooling and fixtures

Tooling and fixtures

Providing you with greater flexibility, a large faceplate is fitted as standard to enable easy

direct fitting of existing tooling. Exclusive tooling/fixture design can also be incorporated offering you a complete solution.

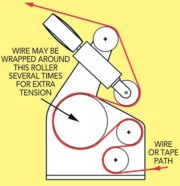

The W-MAW & W-RHD both incorporate a Capstan Tension Unit

For optimum conductor control a range of pneumatically actuated single or double capstan tension units are available. This capstan tension unit is a fabricated steel frame forming a rigid structure onto which all other components are mounted. Four fixing holes are included to fix the unit to the floor.

A capstan wheel is mounted onto a shaft to which a brake disk is mounted for a

pressure regulated brake calliper unit. Increasing the air pressure increases the brake strength thus increasing the tension of the conductor between the tensioner and the next machine in the line. Fleeting wheels are fitted around the capstan wheel to push the cable across the wheel as it rotates. The wheel is guarded all around with an interlocked access door fitted to the front of the unit.

Available in two sizes

| Max.250kg | 2500N |

| Max.500kg | 50000N |

![]() Variable tension control

Variable tension control

![]() Adjustable guide rollers

Adjustable guide rollers

![]() Pneumatic break override

Pneumatic break override

![]() Electrically driven option

Electrically driven option

![]() Center line height can be customized to suit exact requirements

Center line height can be customized to suit exact requirements

Technical Specification

Model

HCP1000 | 2000 | 3000 | 4000

Tooling Space Availability

Max. 325mm W x 250mm H

Pressing Space Availability

Max. 275mm W x 220mm H

Loop Length

1500mm | 2500mm | 3500mm | 4500mm

Pressing Length

1000mm | 2000mm | 3000mm | 4000mm

Heating Temperature

Typically 165 °C

Number of Press Heads

4 | 8 | 12 | 16

Compaction Force

10 Tonnes per cylinder (Horizontal & Vertical)

Hydraulic System

Powered by Air Multiplier

Heater Platerns

Nominally 500mm L x 220mm H x 50mm W

Heater Platern Power

Nominally 12Kw (per heater platen)

Cooling Circuit

With air blast and recyclable water cooling

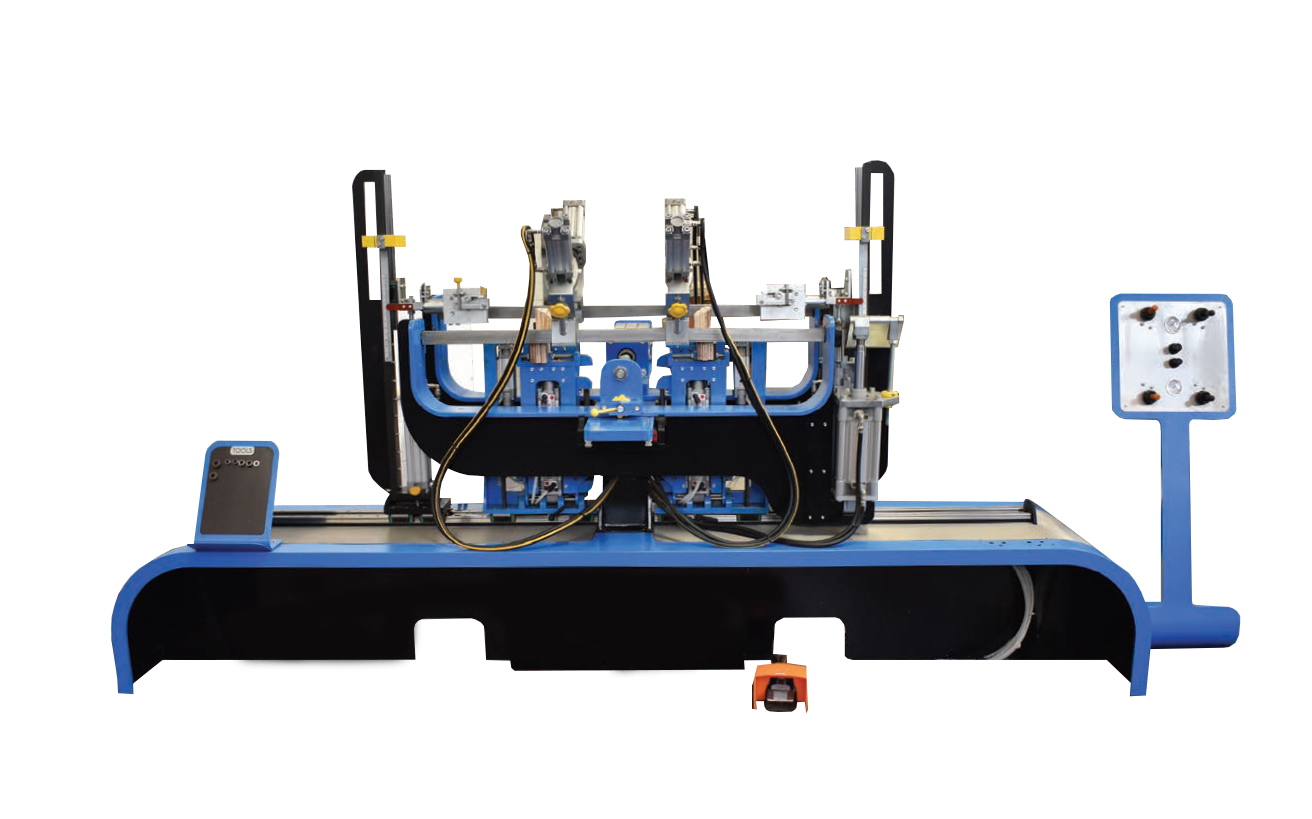

The HCP Hot Coil Compaction Press is designed to heat and consolidate stator coils & bars. Standard models are available however, each machine can be tailored to the customer’s specific requirements.

The HCP incorporates a set of hydraulic rams built into hinged arm assemblies across the top length and rear face of the working envelope, with independent hydraulic circuits. Each ram can deliver 10 tonnes of force and the number of rams can be selected to suit specific coil lengths.

Coil heating is achieved using a set of electrically heated platens (heater bars) at the front and rear sides of the machine. Each platen is independently operated/controlled from a

free standing HMI cabinet.

After pressure is applied, the platen temperature is raised to a set point and held for a period of time (soak time). The platens are then cooled with an air blast followed by recyclable cooling water prior to hydraulic ram release and unloading of the coils.

![]() Full HMI Process Control

Full HMI Process Control

Full HMI operator control is provided from a free standing cabinet. This covers the entire compaction process from hydraulic, air and temperature control to cooling and power consumption for each of the control zones within the machine, including fault diagnosis.

![]() Heater Platens

Heater Platens

Available in a range of sizes

![]() Press space availability

Press space availability

Can be configured to suit exact requirements

![]() Water chiller/ Recirculating Unit

Water chiller/ Recirculating Unit

Interfaced with the HCP through a water manifold arrangement and controlled via the PLC.

HCC – Hot Coil Compaction Press

Designed to heat and consolidate straight loop stator coils

POM-STD – Coil Pull-Out Machine

Technical Specification

Coil stack height

Dependent on tooling

Coil stack width

Dependent on tooling

Slot length

Max: 4064mm

Min: 115mm

Overall loop length (eye to eye)

Max: 5300mm

Min: 875mm

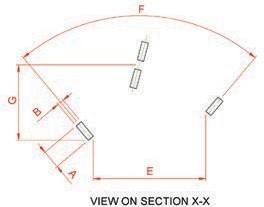

Angle between coil sides

Max: 120° (included)

Min: 0°

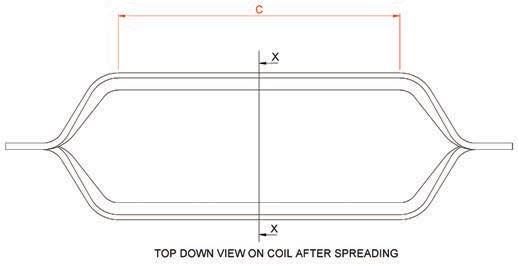

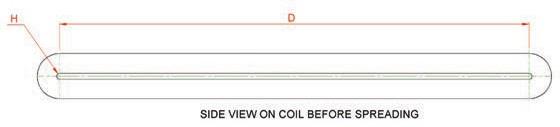

The POM-STD range of coil forming machines are used to spread coils quickly, accurately and efficiently into their final shape according to the coil design.

![]() Capabilities

Capabilities

Pneumatically powered, the POM-STD range has the capability to form stator coils having a maximum loop length of 2500mm with a maximum coil stack size of 60mm x 30mm

![]() Adjustable tooling

Adjustable tooling

Fall away pin type knuckle holders guarantee firm clamping action and quick release. Both the length and the thickness of the coil knuckle holders are adjustable.

![]() Easy to operate

Easy to operate

The coil forming process is driven by using air pressure. Little manual effort is required of the operator. After the loop has been loaded, actuation of a foot pedal closes all four slot clamps simultaneously. The exclusive ballast tank minimizes air supply fluctuations, producing coils smoothly and quickly.

![]() Easy to set

Easy to set

For reference, linear scales are fitted to ensure repeat accurate set ups are quickly and easily achieved.

POM-WPB – Wind & Pull-Out Beam

Technical Specification

Coil stack height

Max: 50mm

Min: 10mm

Coil stack width

Max: 17mm

Min: 5mm

Length of cell (coil straight)

Max: 1520mm

Min: 440mm

Overall loop length (eye to eye)

Max: 2300mm

Min: 756mm

Winder

Maximum torque

Up to 5000 Nm

Speed range

0 to 20 rpm

Bi-directional

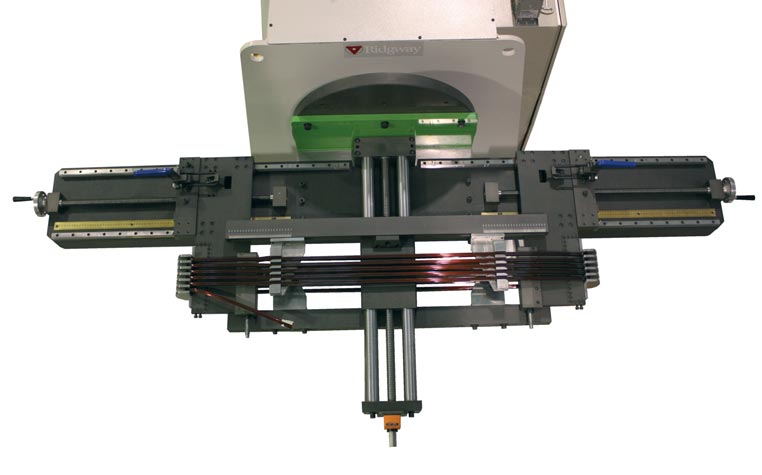

For a versatile and cost effective solution the POM-WPB wind and pull-out beam offers a simple production solution to dramatically reduce the overall coil manufacturing time. The POM-WPB enables phase groups of single and multi-turn coils to be loop wound and pulled-out in one operation.

![]() Quick, accurate set up

Quick, accurate set up

The POM-WPB is fully adjustable. For reference, linear scales are fitted to the beam, ensuring fast and accurate setups can be achieved.

![]() Tooling and fixtures

Tooling and fixtures

Exclusive bespoke tooling design is incorporated, offering a complete manufacturing solution. Variable length

slot section and interchangeable loop bend radius tooling are available.

![]() Turn-key solution

Turn-key solution

The wind and pull-out beam is a standalone fixture designed to fit to an existing winding machine faceplate.

Offering a turn-key solution, to complement the POM-WPB, a complete range of winding machines and drum

stands is also available.

![]() Operator platforms

Operator platforms

Optional work platforms are available, designed to ensure a safe working environment for your operators.

POM-CC – Continuous Coil Forming

Technical Specification

Coil stack height

Dependent on tooling

Coil stack width

Dependent on tooling

Length of cell (coil straight)

Max: 1000mm

Min: 380mm

Overall loop length (eye to eye)

Max: 2000mm

Min: 875mm

Angle between coil sides

Max: 120° (included)

Min: 0°

Coil spread

Max: 900mm

Min: 150mm

The POM-CC range of coil forming machines are used to spread coils quickly, accurately and efficiently into their final shape according to the coil design. Enabling the fast and effective winding of stators, this turn-key production solution dramatically reduces the number of winding

connections required. Simple to operate, production efficiencies of 50% can easily be achieved.

![]() Turn-key solution

Turn-key solution

To complement the POM-CC, a complete range of loop winders, loop winder tooling, turn tapers and drum stands is available.

![]() Precision control

Precision control

Resolver feedback ensures accurate and repeatable positioning of the machine axes.

![]() Tooling and fixtures

Tooling and fixtures

Exclusive bespoke tooling design is incorporated offering a complete manufacturing solution.

![]() Operator HMI control

Operator HMI control

Easy to operate control console via HMI to enable operation of the machine and programming of the pull-out sequences. Coil winding details can also be stored within the control system for future use.

NCT - Narrow Coil Taping Machine

The Ridgway NCT Narrow Coil Taping machine offers an advanced and cost effective automated solution for taping narrow profile wind turbine generator stator coils.

The NCT features a unique multi-axis motion control system with a free standing programmable HMI, making it a truly versatile machine that simplifies the precision taping of all narrow coil configurations, straight or diamond shaped.

The innovative design solves a common problem where traditional taping machines have limited access to both sides of the coil. The coil support system features automatic coil turn-over and height adjustment. This simplifies set-up and eliminates the need to remove or reposition a coil to tape both sides.

![]() Unique Taping Motion

Unique Taping Motion

The NCT uses a unique multi-axis head motion. Lateral movement of the NCT taping head is controlled via a servo motor driven ball screw. This in turn is synchronised with the servo motors that drive the rotational aspects of the taping head. The action of this complex head motion results in a precise process that consistently provides high

quality taped coils.

![]() Constant Tension Control

Constant Tension Control

The Ridgway NCT features constant tension control between 20N and 50N.

![]() Fully Programmable

Fully Programmable

The machine is fully programmable, for example, to set the number of layers required for each coil side, tape pitch and linear speed, the angle of diamond coil legs. Auto reverse at the end of each pass allows for uninterrupted, multiple tape layers without downtime.

![]() User Friendly HMI Control

User Friendly HMI Control

Operated via a user friendly HMI control module, the Ridgway NCT provides the end user with a simple, reliable coil taping solution. For manufacturers of wind turbine generator stator coils, taping productivity and quality will be increased on all narrow coil requirements.

Technical Specification

Rotational Speed

60 rpm max

Tape Width

20mm/25mm

Pitch Capability

5mm to 28mm

Tape Tension

20N to 50N

Tape Angle

+/- 20 °

Coil Length

min 700mm

max 3000mm

Distance Between Coil Sides

min 65mm

max 500mm

Coil Cross Section Height

min 25mm

max 160mm

Coil Cross Section Width

min 10mm

max 25mm

Max Coil Weight

200kg

![]() Taping Head

Taping Head

The taping head rotates around the coil applying a pair of tapes simultaneously with the tensions between 0.5kg and 7.0kg. Tape reel carriers automatically follow the natural angle of the tape being applied to the coil in relation to the coil axis. The MTM head can apply tapes at a rotational speed of up to 250 rpm.

![]() Drive System

Drive System

The MTM uses twin variable speed motors to provide and synchronise the taping head drive and carriage traverse functions. These are controlled by a foot pedal mounted on the taping head carriage, with reversing selection by joystick control.

![]() Coil Support

Coil Support

Pneumatically assisted coil support and clamping system with 3 retractable arms, fully adjustable rear clamp stands and coil eye clamps/supports.

![]() Safe Guarding

Safe Guarding

The MTM is equipped with fixed mesh screen fencing on 3 sides for operator safety. On the open side of the machine enclosure an electronic light sensor guard automatically detects any intrusion and activates the safety circuit, cutting power to stop the machine.

MTM - Mobile Travelling Head Coil Taping

The MTM Mobile/Travelling Head Coil

Taping Machine provides a unique solution to maximise the productivity of applying insulation tapes to larger size electrical coils or bars, with a typical slot length capacity of up to 4000mm.

Ridgway’s MTM is specifically designed for

handling these larger size coils/bars using a

combination of retractable pneumatic coil

supports, adjustable rear clamp stands and coil eye supports. The taping head is

mounted on a mobile carriage which seats the operator and travels along the straight bar or straight leg of coil to be taped, in both directions.

As the carriage approaches the pneumatic coil supports, the clamps open automatically and the support arm moves away to the rear of the machine. The MTM machine can be operated continuously in both directions.

Technical Specification

Rotational Speed

250 rpm max

Tape Width

25mm / 30mm

Tape Head Centre Height

1040mm

Tape Spools

Two Spools ID 55mm/OD 200mm

Tape Tension

0.5kg to 7.0kg

Straight Bar Length

Max. 4000mm

Coil Cross Section

min 50mm x 10mm

max 125mm x 60mm

Air Supply

max. 6 bar

SSC – Straighten, strip and cut machine

for the rapid production of insulated straight bars for armature and rotor manufacture

The SSC line is designed to strip insulation from the ends of pre-insulated copper conductor (supplied on a drum) and deliver them as cut lengths.

A drum of insulated conductor is fed from the pay-off drum stand and through the straightening unit. The conductor is then

pulled through the brush unit stripping the insulation with a counter rotating brush set.

The conductor is pulled through the machine by the caterpillar to a pre-set distance to the second brush unit and the next set of counter-rotating brushes. The

hydraulic guillotine cuts the conductor to length and drops the strip into the collection tray.

The tray indexes after each cut cycle, continuously delivering the final product to the pre-set total length and stripped end lengths.

The SSC line compromises the following modules:

![]() Pay-off Drum Stand

Pay-off Drum Stand

![]() Straightening Unit

Straightening Unit

![]() Brush Stripping & Clean Unit

Brush Stripping & Clean Unit

![]() Extractor

Extractor

![]() Caterpillar

Caterpillar

![]() Guillotine Cut Station

Guillotine Cut Station

![]() Delivery Chute/Collection Bench

Delivery Chute/Collection Bench

![]() HMI Control System

HMI Control System

Technical Specification

Copper Conduction Section

Min – 4mm x 1mm

Max – 18.. x 4mm

Insulation Stripped Length

30mm to 200mm

Conductor Cut Length

500mm to 800mm

Accuracy of Cut Length Conductors & Stripped Length of Ends

+/-2mm

Compressed Air Supply

Clean and dry at 5.5 bar min. pressure

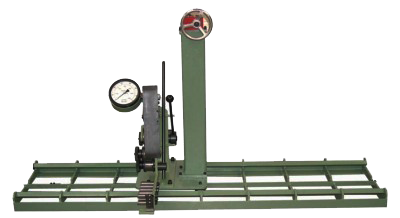

BTU 100 – Band Tension Unit

Designed to apply preset tension to tapes and wires when banding armatures.

Technical Specification

Tension range

Up to 680 kg (1500 lbs)

Maximum tape width

30mm

Maximum wire diameter

3mm Ø

TS Traversing Saddle

Traverse length

1500mm as standard

Custom lengths available

The BTU100 accepts glass fibre tape up to 30mm wide and both round and flat steel wire.

Traversing saddle shown with band tension unit

![]() Tension Control

Tension Control

![]() Tension Adjustment

Tension Adjustment

![]() Straightening

Straightening

![]() Flexible Mounting

Flexible Mounting

![]() TS Traversing Saddle

TS Traversing Saddle