Editorial featured in the September 2019 edition of the IWMA wire and cable news for Wire South East Asia.

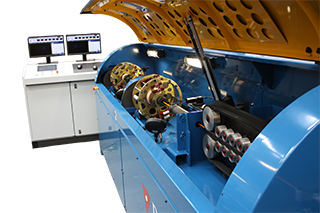

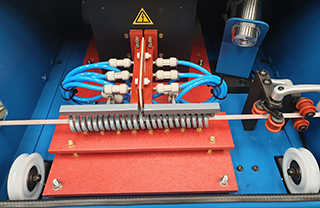

The HTM-MACDC is a new advanced taping line designed to apply a variety of insulation materials such as Kapton, glass and mica to wire, cables and conductors. The new taping lines are designed to maximise productivity whilst minimising costs by giving one technically advanced solution for multiple taping requirements.

The lines comprise of the following; pay off drum stand, straightening unit, taping machines, caterpillars, induction heating unit, varnishing units, radiant oven, nip rollers, recirculating wheels for multi pass applications, cooling systems and take up drum stand.

A camera system is installed on the taping machine to monitor and control the tape being applied to ensure a repeatable, overall higher quality taped product. A Spark tester is also fitted for quality assurance for applicable products. Data capture is also available as an option.

Control systems are plc based with servo drives systems used extensively for precise speed control, especially important for precision tape applications. Heating systems are similarly controlled through the plc with pyrometers providing temperature feedback. An HMI is fitted for easy operator interface and taping application ‘recipes’ can be stored and recalled for quick line setup.

The taping machine successfully completed a rigorous factory acceptance test taping a range of cable and conductors to the highest quality.

Mark Vickers, General Manager – Strip Division at Wire Electric Supplies quoted “The quality of this Taping Line from Ridgway is second to none. It is now installed and producing both products to the very highest standards. We at WES are very happy with all aspects of this machine.”

Andy Clarke, Sales Director at Ridgway Machines commented that “Ridgway have been providing taping machines to the electrical and energy industries for many years and believe our new range of machines provide our customers with the best and most innovative solutions to date enabling them to enter new markets without having to invest in dedicated production lines for either kapton and glass”

Ridgway Machines are a world leading engineering organisation for precision taping and winding machines for the electrical and energy industries. With over 95 years engineering experience supplying technically advanced solutions to industries including aerospace, aviation, automotive, energy, nuclear and subsea.

T: +44 (0)116 289 9199