Other coil manufacturing equipment

Ridgway Machines manufactures a full range of Coil Manufacturing Equipment.

Straigthen, strip and cut machine

for the rapid production of insulated straight bars for armature and rotor manufacture

The SSC line is designed to strip insulation from the ends of preinsulated copper conductor (supplied on a drum) and deliver them as cut lengths.

A drum of insulated conductor is fed from the pay-off drum stand and through the straightening unit. The conductor is then

pulled through the brush unit stripping the insulation with a counter rotating brush set.

The conductor is pulled through the machine by the caterpillar to a pre-set distance to the second brush unit and the next set of counter-rotating brushes. The

hydraulic guillotine cuts the conductor to length and drops the strip into the collection tray.

The tray indexes after each cut cycle, continuously delivering the final product to the pre-set total length and stripped end lengths.

The SSC line compromises the following modules:

![]() Pay-off Drum Stand

Pay-off Drum Stand

![]() Straightening Unit

Straightening Unit

![]() Brush Stripping & Clean Unit

Brush Stripping & Clean Unit

![]() Extractor

Extractor

![]() Caterpillar

Caterpillar

![]() Guillotine Cut Station

Guillotine Cut Station

![]() Delivery Chute/Collection Bench

Delivery Chute/Collection Bench

![]() HMI Control System

HMI Control System

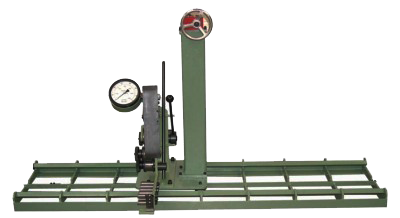

Ridgway BTU 100

Band Tension Unit

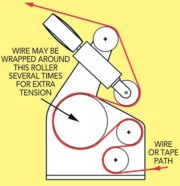

Designed to apply preset tension to tapes and wires when banding armatures.

Technical Specification

Tension range

Up to 680 kg (1500 lbs)

Maximum tape width

30mm

Maximum wire diameter

3mm Ø

TS Traversing Saddle

Traverse length

1500mm as standard

Custom lengths available

The BTU100 accepts glass fibre tape up to 30mm wide and both round and flat steel wire.

Traversing saddle shown with band tension unit

![]() Tension Control

Tension Control

![]() Tension Adjustment

Tension Adjustment

![]() Straightening

Straightening

![]() Flexible Mounting

Flexible Mounting

![]() TS Traversing Saddle

TS Traversing Saddle

This capstan tension unit is a fabricated steel frame forming a rigid structure onto which all other components are mounted. Four fixing holes are included to fix the unit to the floor.

A capstan wheel is mounted onto a shaft to which a brake disk is mounted for a

pressure regulated brake calliper unit. Increasing the air pressure increases the brake strength thus increasing the tension of the conductor between the tensioner and the next machine in the line.

Fleeting wheels are fitted around the capstan wheel to push the cable across the wheel as it rotates.

The wheel is guarded all around with an interlocked access door fitted to the front

of the unit.

Available in two sizes

| Max.250kg | 2500N |

| Max.500kg | 50000N |

![]() Pneumatic brake override

Pneumatic brake override

![]() Adjustable guide rollers

Adjustable guide rollers

![]() Variable tension control

Variable tension control

![]() Center line height can be customised to suit exact requirements

Center line height can be customised to suit exact requirements

Capstan Tension Unit

For optimum conductor control a range of pneumatically actuated single or double capstan tension units are available.