RTP & TCP Taping MAchines

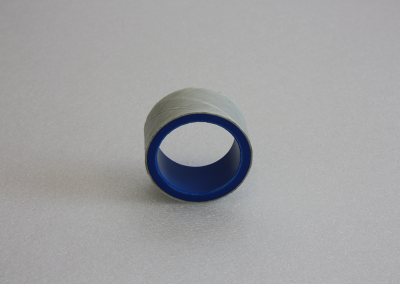

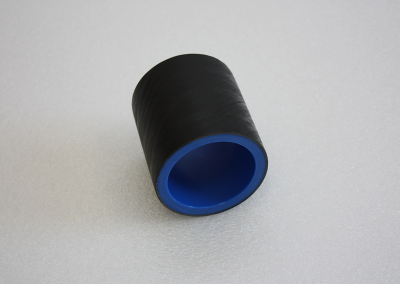

Designed to apply layers of tape (Kevlar®, glass etc.) onto plastic liners in the manufacture of Reinforced Thermoplastic Pipe (RTP) & Thermoplastic Composite Pipe (TCP)Each head applies multiple tapes with standard tape tensions up to 1kN. The machine follows a signal from an upstream caterpillar and, with the use of dedicated software, lays the tapes accurately to the required specification. Typically supplied in multiples of 2 tape heads, the heads rotate in opposite directions to cancel out the rotation forces generated when applying the tapes.

Up to 16 RTP taping machines can be configured in an RTP taping line to provide multiple reinforcement layers.

The pipe made by these machines is widely used in the oil & gas, and water and district heating markets.

Ridgway also supply heating and consolidation units to fuse each reinforcement layer in the manufacture of Thermoplastic Composite Pipe (TCP).