CABLE AND CONDUCTOR TAPING MACHINES

Ridgway design and manufacture a range of vertical and horizontal cable and conductor taping machines.

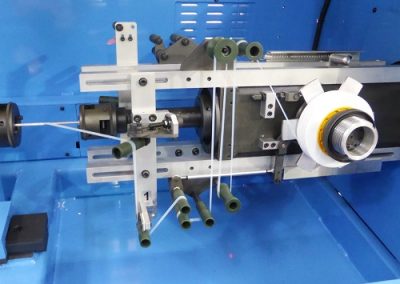

High Speed Precision Taping Machine

Designed to accurately apply a variety of tape materials for high frequency cables and flat conductors for the Aircraft, Aerospace and Satellite System Industries.

The machine can apply a variety of high performance materials to wire and cable including PTFE, Aluminium, Mylar and Kapton.

It has servo controlled taping heads with electronic tape tension control and is capable of applying 1 tape from flat pads or cross wound (universal) pads.

Hi-Resolution 5MP cameras are integrated into the machine to provide high quality multi-point vision inspection, adjustment and image capture.

To enhance the finished product the camera system monitors tape elongation, overlap, registration and contamination for overall better quality and control.

A range of optional extras are also available to complement and strengthen the taping line.

High Speed Compact Taping Machines

The taping lines are designed to precisely apply up to 2 individual tapes per head onto round or rectangle wires.

Twin servo motor technology ensures the fast and accurate application of the applied tapes. The taping head is designed to accommodate both flat and cross wound tape pads to suit the required application. The HTM-Configurations can be used to apply a variety of materials including but not limited to Mica, Paper, Nomex®, Polyester, Aluminium/Mylar and Kapton®.

An easy to operate operator HMI control panel allows for fine adjustments to the head speeds, taping lap and jog movement. Take up drum stand settings are also handled through the HMI and line status information is also displayed.

Kapton and Glass Taping Line

The line can be designed to apply one or both applications based on your requirements.

Designed to insulate round or flat conductors by applying

Kapton® tape or Glass then bonding by heat applied by induction and

radiant ovens.

control available.

powered brushes ensure that the

conductor is perfectly straight and clean

servo concentric taping head

speed. Pneumatically controlled belt pressure.

system. Air wipe attached for conductor

drying.

chain for finished product quality

control.

between all line elements including

ancillary equipment.

of conductor layering. Dancer controlled

variable torque geared motor,

combined with ultrasonic sensors

ensures precise conductor tension

throughout the winding process.

High Speed Tangential Taping Machines

for wire and cable

High speed accurate taping at up to 60 metres/minute. Available in 2 – 4 tape pads per head dependent on your requirements.

High Capacity Concentric Taping Machine

Designed for the application of tape to wire and cable

The high capacity concentric taping head gives you the opportunity to tape continuously for up to 24 hours without a tape pad change.

Integrated reserve tube for tape pad storage. Flat pads can also be used if required.

Increase your productivity by investing in

competitively priced high quality precision taping machines.

range of materials to meet the high

standards your customer demands.

latest twin servo drive technology.

low pad detection.

High Speed Horizontal Bunching Line

For taping and bunching wire and cable – up to 8 Separate Conductors

A complete solution offering the capability to separately insulate, bunch and collectively insulate stacks of conductor.

Ridgway offer a complete automated machine line for taping and bunching multiple conductors together. Taping insulation material is applied onto the individual conductors (up to 8 maximum) prior to bunching and collectively insulating the finished conductor stacks.

Taping speeds in excess of 1000rpm can be provided with a choice of 2, 3, 4 or 8 pad heads for each individual taping bay to provide the required quantity of insulation layers. A full graphics HMI interface provides simplified control from a single free standing console.

If space is a constraint, we can design a compact unit to suit your exact requirements.

Ridgway Vertical Taping Machine

Designed to apply a large range of taping materials to conductors and cables.

The heads are electronically linked through a dancer unit, which provides extremely accurate tape tension control throughout the taping process. The dancer detects tape breakage and instructs the machine to come to a rapid controlled stop.

The operator inputs taping parameters and the helix angle is displayed to enable tape head set up – a recipe memory is included in the control system to allow the operator to create, save and load taping recipes.