Drum stands

Extensive range for all applications

Designed to meet the needs of all cable & wire manufacturers

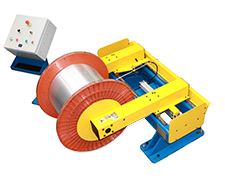

Robust drum stands with capacities up to 16 tonnes can be supplied in both pay-off and take-up variants. Options vary from simple pressure brakes through to torque and dancer control systems. Manual, pneumatic, hydraulic and electrical lift systems are available to suit the application.

Ridgway 26 Pay Off Drum Stand

Pay-Offs and Take-Ups with precise layering

and tension control

![]() Types available

Types available

- Gantry

- Pintle

- Shaft

- Vertical

![]() Options

Options

- Powered drum lift

- Powered pay off

- Traversing drum

- Servo driven

- Traversing wire

- Uhing type

- Drum Ø sensing

- Variable torque control

- Dancers/Accumulators

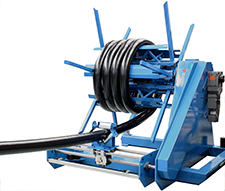

Multi Position Pivoting De-Reeler Drum Stand

The sixteen drum pay off drum stand features 16 separate cantilevered drum shafts, each with twin bearing units, mounted in a steel frame. The number of drum positions can be configured to suit individual customer requirements.

The drums are mounted to the drum shafts by means of tapered cones to accept a range of drum bore sizes. These drum shafts also carry the back tension brake – tension adjustment for each drum is provided via a cylinder connected to a lever valve and a pressure regulator.

The steel frame is in turn fixed to a front and rear support structure, with a bearing system that enables the drum frame to rotate through 180 degrees. Rotation is via a motor and drive system, controlled from the operator’s control panel located adjacent to the drum stand.

For safety reasons the drum stand rotates at low revolutions (10rpm typical) and rotational operation requires constant two handed operation.

The system is designed to rotate 180 degrees in one direction then back again, enabling a transposition turn to be put into a wound loop.

Integration with Ridgway Coil Manufacturing

The Multi Position Pivoting De-Reeler Drum Stand can be used with a range of Ridgway coil manufacturing machinery.

Technical Specification

Maximum drum diameter

to DIN 630

Maximum drum width

to DIN 630

Maximum drum weight

160 kg

Drum shaft diameter

Ø 32mm

Electrical supply

415 Volts, 3 Phase, 50 Hz

(other supplies catered for)

Compressed air supply

Clean and dry at 2cfm at 5.5 bar