BCT Coil Taping Machines

Designed for cost effective, quality insulation for motor and generator coils and bars. Designed for the fast, precision application of tape insulation systems to a wide variety of components – including motor and generator stator coils and bars. BCT Suspended Coil Taping Machines provide the ultimate solution to dramatically improve your production capabilities.BCT COIL TAPING SYSTEMS

Ridgway’s BCT model range is specifically designed for the application of tape insulation systems to motor and generator coils and bars. It is designed for both OEM and repair shop, providing cost effective, quality insulation.Ease of operation

The taping head is weightlessly suspended from an overhead trackway, and provides a fast, acccurate and consistent method of operator guided mechanised tape application with virtually no preparation or set up time being required.

BCT 16/30VL

| Cross Section of Conductor to be taped (max): 16mm x 30mm |

| Capacity: Cross Section of Conductor to be taped (min): 5mm x 10mm |

| Tape Width: 15mm or 20mm |

| Lap: Variable |

| Tape Spool – Core Ø 25mm |

| Tape Spool – Outside Diameter Ø 80mm or 90mm |

| Taping Speed: 250 rpm max |

| Distance Between Coil Legs for Access: 115mm min |

| Air Supply Pressure: 5.5 Bar |

| Recommended Min Bore: Ø 12mm |

| Free Air Use at Full Speed: 18 litres / sec |

BCT 20/50VL

| Cross Section of Conductor to be taped (max): 20mm x 50mm |

| Capacity: Cross Section of Conductor to be taped (min): 10mm x 18mm |

| Tape Width: 20mm or 25mm |

| Lap: Variable |

| Tape Spool – Core Ø 25mm |

| Tape Spool – Outside Diameter Ø 110mm |

| Taping Speed: 240 rpm max |

| Distance Between Coil Legs for Access: 200mm min |

| Air Supply Pressure: 5.5 Bar |

| Recommended Min Bore: Ø 12mm |

| Free Air Use at Full Speed: 18 litres / sec |

BCT 35/100VL

| Cross Section of Conductor to be taped (max): 35mm x 100mm |

| Capacity: Cross Section of Conductor to be taped (min): 15mm x 30mm |

| Tape Width: 20mm or 25mm |

| Lap: Variable |

| Tape Spool – Core Ø 25mm to 55mm |

| Tape Spool – Outside Diameter Ø 170mm |

| Taping Speed: 200 rpm max |

| Distance Between Coil Legs for Access: 350mm min |

| Air Supply Pressure: 5.5 Bar |

| Recommended Min Bore: Ø 12mm |

| Free Air Use at Full Speed: 18 litres / sec |

BCT 50/150VL

| Cross Section of Conductor to be taped (max): 50mm x 150mm |

| Capacity: Cross Section of Conductor to be taped (min): 25mm x 45mm |

| Tape Width: 20mm, 25mm or 30mm |

| Lap: Variable |

| Tape Spool – Core Ø 25mm to 55mm |

| Tape Spool – Outside Diameter Ø 170mm |

| Taping Speed: 150 rpm max |

| Distance Between Coil Legs for Access: 350mm min |

| Air Supply Pressure: 5.5 Bar |

| Recommended Min Bore: Ø 12mm |

| Free Air Use at Full Speed: 26 litres / sec |

EVEN GREATER PRODUCTION

The taping head uses low or high resin tapes for OEM or repair coil shops. It applies tapes over the “in-slot” area and end legs of the coil or bar. In the case of a closed coil the length of covering is limited only by the clearance for head access. Especially useful on longer, heavier coils – the optional coil turnover unit enables both sides of a coil to be taped with speed and convenience.

Ridgway BCT-VLDM

Cost Effective Bench Mounted Taping Machine Improves Coil Manufacturing Productivity. The Ridgway BCT suspended coil taping machine is also available in a convenient bench mounted configuration. This provides a self-contained and cost effective solution for improving the productivity and quality of manually operated coil taping lines. The BCT Bench machine is ideal for taping smaller and open coils and bars, for applications such as motor and generator stators. Two layers can be applied simultaneously and the BCT tapes in both directions. The machine is pneumatically operated, by a series of pneumatic foot pedals that control the clamp facility, traverse direction and taping speed, at speeds up to 250 rpm with no electrical power required. The Ridgway BCT-VLDM series is available in 2 sizes: BCT 16/30VLDM BCT 20/50VLDM

|

Bench-Mounted BCT Model |

BCT 16/30VLDM |

BCT 20/50VLDM |

|---|---|---|

| Capacity: Cross Section of Conductor to be taped (max/min) |

16mm x 30mm

5mm x10mm |

20mm x 50mm

10mm x 18mm |

| Tape Width |

15mm or 20mm |

20mm or 25mm |

| Lap |

Variable |

Variable |

| Tape Spool – Core |

Ø 25mm |

Ø 25mm |

| Tape Spool – Outside Diameter |

Ø 80mm or 90mm |

Ø 110mm |

| Taping Speed |

250 rpm max |

240 rpm max |

| Distance Between Coil Legs for Access |

115mm min |

200mm min |

| Air Supply |

5.5 Bar Pressure |

5.5 Bar Pressure |

| Recommended Min Bore |

Ø 12mm |

Ø 12mm |

| Free Air Use at Full Speed |

18 litres / sec |

18 litres / sec |

| Bench Size | W 106cm x D 72cm x H 84cm | |

BCT COIL HANDLING EQUIPMENT

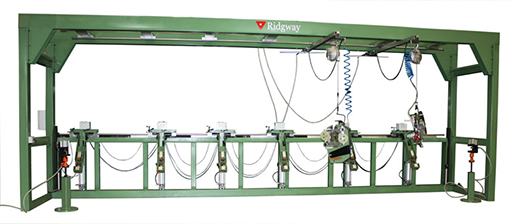

Coil Handling System with Suspended Taping Head Improves Manufacturing Productivity Ridgway BCT hand-held taping machines are available with a range of gantry systems, particularly useful for taping larger or heavy coils. Designed as a complete workstation, the gantry enables the pneumatic BCT to be weightlessly suspended for ease of operation. In addition, a Coil Turnover Unit allows quick height setting and rotation of the coil to tape both sides. Productivity is increased and a consistently high quality tape application achieved.

COIL TURNOVER UNIT 2500

COIL TURNOVER UNIT 3000

COIL TURNOVER UNIT 4000

COIL TURNOVER UNIT 5000

Turn Taping Gantry

The unit is used as a suspension gantry to hold a ‘BCT’ taping machine or Squirrel Turn Taping machine to apply a variety of insulation tapes to a conductor prior to coil winding.

The taping machine is suspended from a linear rail mounted to the underneath of the gantry overhead beam.

The gantry should be positioned such that the taping machines can be used as close to the loop winding pins as possible without causing damage to either machine when the winding beam is rotated.

The Squirrel Turn Taping Machine can be used with the turn taping gantry. Controlled via an easy to use operator pedestal.

![]() Designed as a workstation to weightlessly suspend BCT taping machines

Designed as a workstation to weightlessly suspend BCT taping machines

![]() Flexible design to fit available space

Flexible design to fit available space

![]() A free-running carriage mounted to linear rails nensures smooth lateral motion of the taping head

A free-running carriage mounted to linear rails nensures smooth lateral motion of the taping head

![]() Space saving design

Space saving design

![]() Quick and easy connection of the taping machine to the pneumatic circuit

Quick and easy connection of the taping machine to the pneumatic circuit

Gantry with CTU

Increase your production effectiveness by complementing the range of BCT taping machines with Ridgway’s selection of dedicated handling equipment. Use Ridgway gantry workstations with CTU coil turnover units to provide fast, accurate and consistent methods of operator guided tape application with virtually no preparation or set up time required.

BCT Coil Supports and Clamps

A range of supports and clamps specially designed to increase BCT coil taping productivity.Retractable Front Supports

Freestanding retractable front support designed for quick and easy operation. Comprising of an air cylinder with an adjustable soft top, enabling the desired work height to be achieved. Cylinder up and down movement is actuated via a foot pedal.Rear Supports

Freestanding rear support designed for quick and easy operation. Manual vertical adjustment.Clamps

All clamps are robustly designed and pneumatically actuated via a foot pedal.Ridgway Bar Support Gantry

Designed to clamp and support large stator bars while taping with BCT taping machines. For a versatile and cost effective solution, when used in conjunction with the range of Ridgway BCT taping machines, the bar support gantry provides a secure method of supporting large stator bars during the taping process. With precision, overhead linear guide rails and automatic retraction of the bar supports, the operator can tape the entire length of the stator bar without interruption.![]() Quality

Quality

![]() Automatic retraction

Automatic retraction

![]() Lateral positioning

Lateral positioning

BSG Technical Specification

![]() Height adjustment

Height adjustment

![]() Flexible

Flexible

![]() Overhead linear rails

Overhead linear rails

![]() End clamping

End clamping

![]() Multiple BCT carriages

Multiple BCT carriages

Flat Coil Technical Specification

Width 1810 mm

Depth 1470 mm

Height (max) 1480 mm

Height (min) 960 mm

Mass 360 kg

![]() Improved Quality

Improved Quality

Designed for fast, precision application of tape insulation systems

![]() Speed

Speed

Effortlessly tape at upto 8 times faster than traditional methods

![]() Ease of use

Ease of use

Easiliy adjustable bench height for best working height for multiple operators

![]() BiDirectional

BiDirectional

Apply tape in both direction via foot pedal control without adjusting set up

![]() Overlap

Overlap

Variable tape overlap selection suitable for a wide variety of tapes and tape widths

Flat Coil Bench Mounted BCT

The bench mounted BCT is ideal for taping smaller and open coils that can easily be manipulated by hand.

The BCT is exactly the same as the suspended design but is mounted in a workbench. Opeartor of the bench mounted configuration is control via foot pedals, leaving the operators hands free to guide the coil be taped.